Re: Jedo's Volero Dart Resto...

Now awaiting delivery of Gelcoat.

The whole hull will be scuffed and 3 layers of Gelcoat rolled on - with final layer of gelcoat + wax rolled on... Flattened and buffed...

Gunwhales will be painted same as top...

The hull will then be put back on the trailer, suitably chocked and braced and I will replace the transom first.

The transom timber is 1" A-Grade Marine Ply (expen$ive..!!) and I will add 1/2" marine ply to this to make a sandwich of 1.1/2 inches.

The sandwich will be well wetted and have a filling of 600g csm and resin, and be overwrapped with 600g csm... and then clamped to the outer transom skin with a PB mix and allowed to bond for 48 hrs...

Next will be to replace the stringers...

Consternation again with what timber to use?

Seriously considered Kapur... very heavy and 'spelky': the considered Indonesian Mahogany... again very heavy...

Now... having read dozens of articles and references and posts on a range of forums re "stringer material" we have reached the following conclusions:

The timber does not 'need' to be heavy - balsa and even foam are widely used...

Neither does it need to be inherently rigid - cardboard is used...

The stiffness and rigidity of the stringers is supplied by the FG encasing the stringers... some manufacturers use hollow pre-formed box construction FG...

No Timber is guaranteed to be completely resistant to the effects of water, over time... (some timbers are less-resistant than others)

Given that the viable lifetime of the restored Volero is a possible maximum 10 yrs (if it floats at all) the choice of timber / material for the stringers is less important than the protection affordedby the applied FG...

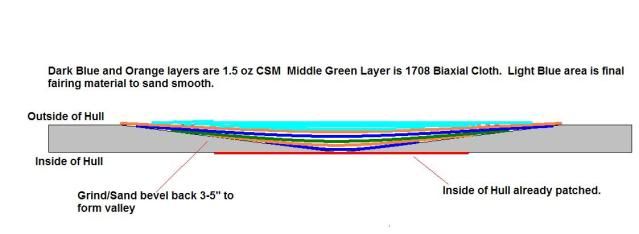

The superstructure of the boat is less-technically demanding: Inspection showed many holes drilled by previous owners. These are in the process of being backed and PB filled, then ground externally to a taper, glassed over, bodged and primed. I have sanded off all cracked and loose paint / gelcoat, and sanded out many small blisters. All will be primed with "primer + putty" spray, then final finish coat.

A fair bit of work already done - more still to yet do...