BWR1953

Admiral

- Joined

- Jan 23, 2009

- Messages

- 6,525

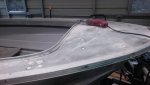

I did some more hole filling by myself this morning. Man, there were a lot of holes. Still have some left that I can't reach! The boy will have to do those. And I ended up having to use a heating pad on my knee for a couple hours after my work this morning. D'oh.

Still plenty of work to do before the hull is ready to paint. Slow I know, but getting there...

Went back out this evening and removed the anchor chock from the bow nose cap and discovered that the cap wasn't actually fastened down at all. I could slide it back and forth across the bow, revealing gunk underneath. That will all be cleaned up prior to painting.

I could slide it back and forth across the bow, revealing gunk underneath. That will all be cleaned up prior to painting.

The cap will be riveted down after I fill a few holes.

Still plenty of work to do before the hull is ready to paint. Slow I know, but getting there...

Went back out this evening and removed the anchor chock from the bow nose cap and discovered that the cap wasn't actually fastened down at all.

The cap will be riveted down after I fill a few holes.