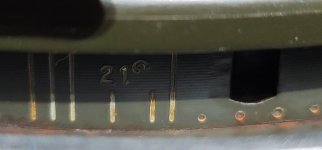

Rookie needs help reading timing scale. This reading was taken at idle. Arrows are pretty close. I'm just a beginner with lots to learn and going slow.

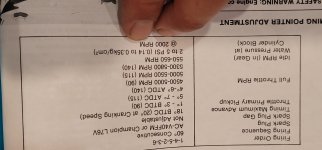

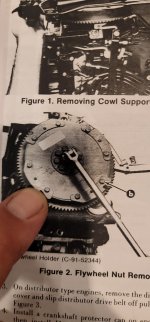

Posted a picture of the pointer with timing lighr, the scale as well as manual.

Can someone tell me what the number is being displayed?

Engine runs okay with exception of poor idle. That's for another thread.

Full disclosure; when I was given this motor, all the bolts on the flywheel (except center) were loose. So I don't trust the position of the pointer.

I tried the initial setting of pointer at 464 using dial indicator but assume I'm doing something wrong since 464 was nowhere near the pointer when I followed procedure in book. I may not understand TDC i.e. rotated flywheel counterclockwise until piston was at its height closest to spark plug hole, then zeroed the dial indicator, them turned the flywheel counterclockwise until dial show 464. 464 mark on flywheel was a long was away ie quarter way round the wheel.

My check of timing was to get a second indicator if the flywheel might have been thrown back on without regard to scale.

Any info to help me ensure placement of flywheel and or just tell me the reading displayed in picture is greatly appreciated.

Posted a picture of the pointer with timing lighr, the scale as well as manual.

Can someone tell me what the number is being displayed?

Engine runs okay with exception of poor idle. That's for another thread.

Full disclosure; when I was given this motor, all the bolts on the flywheel (except center) were loose. So I don't trust the position of the pointer.

I tried the initial setting of pointer at 464 using dial indicator but assume I'm doing something wrong since 464 was nowhere near the pointer when I followed procedure in book. I may not understand TDC i.e. rotated flywheel counterclockwise until piston was at its height closest to spark plug hole, then zeroed the dial indicator, them turned the flywheel counterclockwise until dial show 464. 464 mark on flywheel was a long was away ie quarter way round the wheel.

My check of timing was to get a second indicator if the flywheel might have been thrown back on without regard to scale.

Any info to help me ensure placement of flywheel and or just tell me the reading displayed in picture is greatly appreciated.