DeepBlue2010

Lieutenant

- Joined

- Aug 19, 2010

- Messages

- 1,305

I appreciate all of the help thus far. I don't know if I will have time to do much work on it this week but I should be able to get some photo's posted for your inspection and added insights this evening.

DeepBlue2010 ,

In your earlier post, you talked about feathering. Am I understanding it right by thinking that you mean reducing the thickness? I believe it is about 3/8 to 1/2" thick at present state. How much should I reduce the thickness at the edge?

Yes, feathering is to gradually reduce the thickness of the laminate from total thickness farther away from the cut to a shallow depth of either greater than half or almost to nothing near the cut depends on how are you going to proceed with the repair.

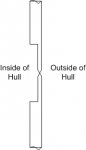

If you are going to feather and glass from both sides (front and back) as I described, the edges should be feathered from both sides to meet at an edge right in the middle like this shape >

You can do this in 2 stages; You can start by feathering one side just past half of the total thicness of the laminate (the part you cut out), glass it and go back to the other side and feather and glass. You will ne grinding through the new glass you just put on the side you started with but this is not a bad thing. You will be applying new glass over it again anyway.

If you will be fixing from one side only. Feather to an edge on the opposite side of the repair. Like a chisel blade shape.

Some repair shops will argue that the repair is requird on one side only and the wood of the transom is all you need to support the inside part of the repair. Be that as it may, saving time and efforts and charging you for a complete repair anyway or a legitimate argument, I would not do it this way. I am working for myself and I am not trying to save few bucks so I will fix it the way I want it. Doesn't mean it is the only way to do, it is just what I would do.

Last edited: