MalibuMike

Petty Officer 2nd Class

- Joined

- Dec 29, 2020

- Messages

- 137

I found oil in my bilge and reached under to feel where it might be coming from. I had heard about the dreaded rust blisters that can form on the oil pan and found one. I'll do one more check to make sure the leak isn't from the dipstick gasket or nut or the bottom of the timing chain cover, but I could use some advice on how to pull the engine and what to do while it's out. I'll have access to a forklift so that solves a major issue. I'll add my question below. Even if you can only answer one, I'd be very grateful! Engine is a VP 5.7 from 2007 ( Vortex Heads, Crab cap distributer)

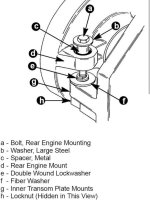

1) I see two adjustable forward motor mounts and two rear mounts that I think are on the bell housing. Assuming I've disconnected everything else that should come off prior to an engine pull, what do I disconnect at the back to free the engine? Is it just the bell housing? Or does that come up with the engine once the driveshaft is out? I'll have about 6-8 inches forward travel to slide the engine forward. Does the outdrive always have to come off or is that figured out with how much room I have to slide the engine forward?

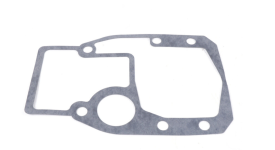

2) Once it's pulled, what other maintenance items should I tackle? Bearings or gaskets? I think I'll have access to the flex plate and a rear main seal. Any gaskets on the inside of the transom where the outdrive mounts? Y pipe gaskets? I'd like to replace anything easy and relatively inexpensive.

3) My Front motor mounts look rusty and I should probably change them while out. Will this trigger an alignment even if I am careful with setting the same heights? I think I understand the basic of an alignment. The driveshaft needs to go thru the carrier bearing and be straight when it inserts in to the back of the motor. The alignment tool just helps you figure out if everything is lined up if it feels like it spins nicely in the bearing without binding. Hope that is right.

1) I see two adjustable forward motor mounts and two rear mounts that I think are on the bell housing. Assuming I've disconnected everything else that should come off prior to an engine pull, what do I disconnect at the back to free the engine? Is it just the bell housing? Or does that come up with the engine once the driveshaft is out? I'll have about 6-8 inches forward travel to slide the engine forward. Does the outdrive always have to come off or is that figured out with how much room I have to slide the engine forward?

2) Once it's pulled, what other maintenance items should I tackle? Bearings or gaskets? I think I'll have access to the flex plate and a rear main seal. Any gaskets on the inside of the transom where the outdrive mounts? Y pipe gaskets? I'd like to replace anything easy and relatively inexpensive.

3) My Front motor mounts look rusty and I should probably change them while out. Will this trigger an alignment even if I am careful with setting the same heights? I think I understand the basic of an alignment. The driveshaft needs to go thru the carrier bearing and be straight when it inserts in to the back of the motor. The alignment tool just helps you figure out if everything is lined up if it feels like it spins nicely in the bearing without binding. Hope that is right.