MalibuMike

Petty Officer 2nd Class

- Joined

- Dec 29, 2020

- Messages

- 137

OK quick update. I managed to pull the drive off by myself without any type of accessory. I just rested the skeg on a piece of wood and shook it off and manhandled it.

I wanted to share some pictures of what I found and get any more recommendations.

The U joint did not show any signs of water intrusion and all the grease had its natural color. Shook it around and couldn’t find any sloppiness or binding. Inside of the bellow I saw lots of original grease and again no signs of water.

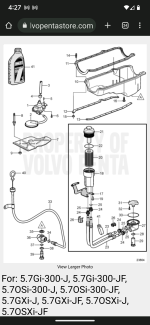

There was a decent amount of corrosion in the water tube area. Should this little gasket automatically be replaced? What degrees do you recommend I push into the U joint? The mechanic who serviced it a year and a half ago use some sort of dark burgundy brown stuff.

I wanted to share some pictures of what I found and get any more recommendations.

The U joint did not show any signs of water intrusion and all the grease had its natural color. Shook it around and couldn’t find any sloppiness or binding. Inside of the bellow I saw lots of original grease and again no signs of water.

There was a decent amount of corrosion in the water tube area. Should this little gasket automatically be replaced? What degrees do you recommend I push into the U joint? The mechanic who serviced it a year and a half ago use some sort of dark burgundy brown stuff.

Attachments

-

A4F477B2-77DD-4775-9B58-89005884F9A7.jpeg2 MB · Views: 10

A4F477B2-77DD-4775-9B58-89005884F9A7.jpeg2 MB · Views: 10 -

D4C0B692-535E-450B-8124-3A5D7889D666.jpeg2.3 MB · Views: 8

D4C0B692-535E-450B-8124-3A5D7889D666.jpeg2.3 MB · Views: 8 -

9276EBA9-056D-4AA3-8227-A433ED8D17B7.jpeg2 MB · Views: 11

9276EBA9-056D-4AA3-8227-A433ED8D17B7.jpeg2 MB · Views: 11 -

71D52828-DCBB-41ED-961F-27C9337A0E61.jpeg1.8 MB · Views: 12

71D52828-DCBB-41ED-961F-27C9337A0E61.jpeg1.8 MB · Views: 12 -

C75DB66B-AACC-489C-A110-D3F4AD5E103E.jpeg1.9 MB · Views: 12

C75DB66B-AACC-489C-A110-D3F4AD5E103E.jpeg1.9 MB · Views: 12 -

04AFCB5D-EF00-433A-9A30-F42530582E0A.jpeg1.4 MB · Views: 9

04AFCB5D-EF00-433A-9A30-F42530582E0A.jpeg1.4 MB · Views: 9 -

177610D2-D9E3-4247-BEDF-31EB219D2CA2.jpeg1.7 MB · Views: 9

177610D2-D9E3-4247-BEDF-31EB219D2CA2.jpeg1.7 MB · Views: 9 -

C1D7F16F-6D61-4EF4-8E05-41EB1607F54E.jpeg4.5 MB · Views: 9

C1D7F16F-6D61-4EF4-8E05-41EB1607F54E.jpeg4.5 MB · Views: 9