Red Herring

Chief Petty Officer

- Joined

- Oct 1, 2012

- Messages

- 536

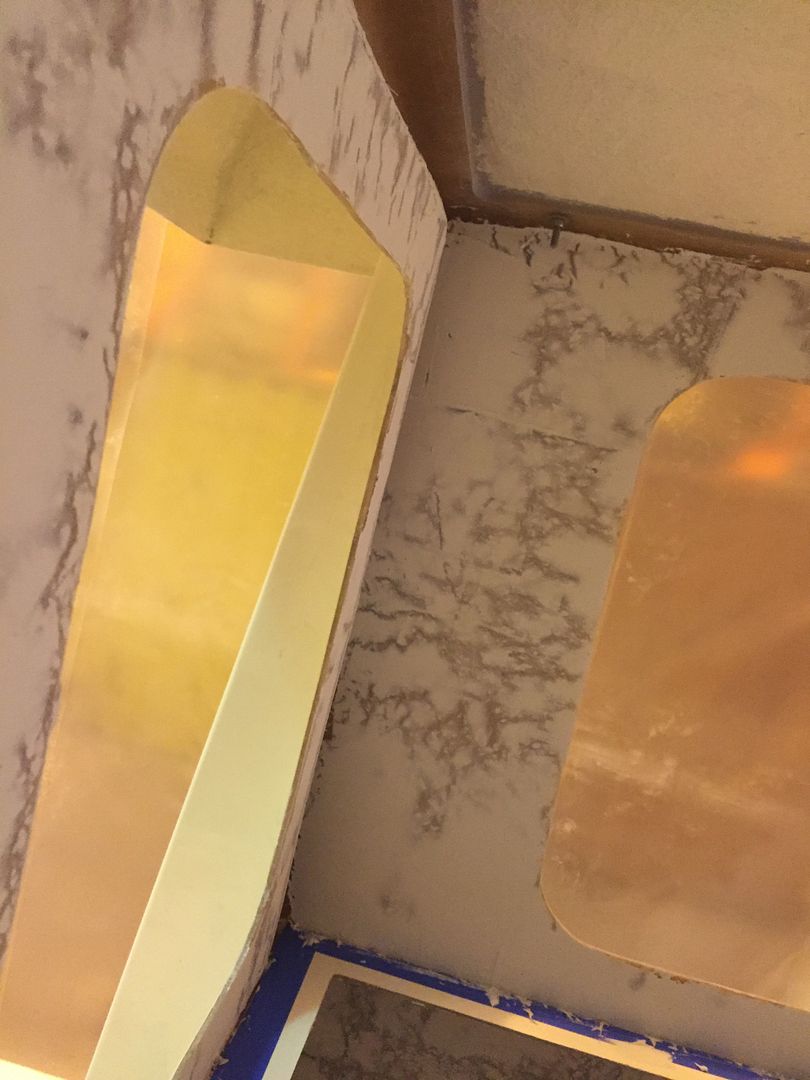

Thanks, I'm looking forward to the final matte-layers of varnish, this glossy stuff isn't really my thing. Sanded through the veneer in one spot that luckily isn't very visible.

The thin veneer on the plywood will become a serious pita if I'll need to redo the varnishing. So now we decided to seriously overdo the initial layer for more longevity. Aiming for maybe 15 coats or even more.

The thin veneer on the plywood will become a serious pita if I'll need to redo the varnishing. So now we decided to seriously overdo the initial layer for more longevity. Aiming for maybe 15 coats or even more.

Last edited: