TriadSteeler

Petty Officer 1st Class

- Joined

- Oct 26, 2006

- Messages

- 237

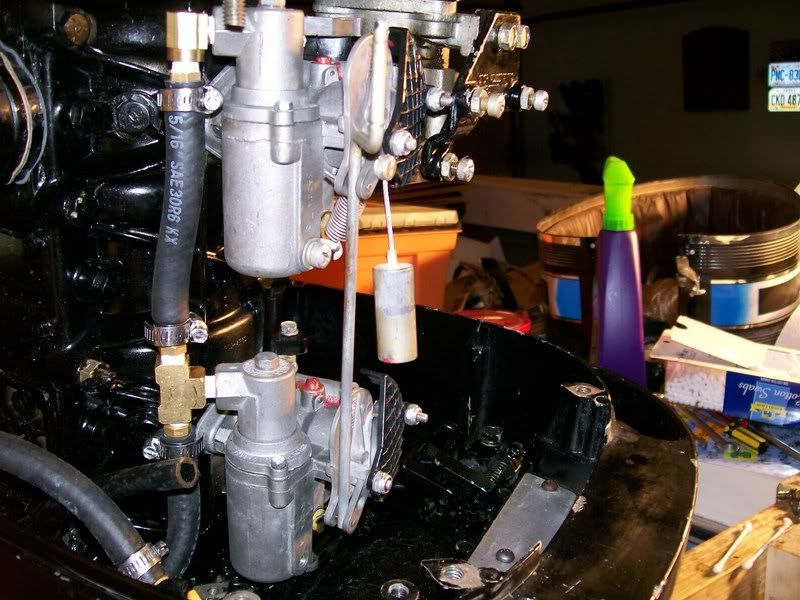

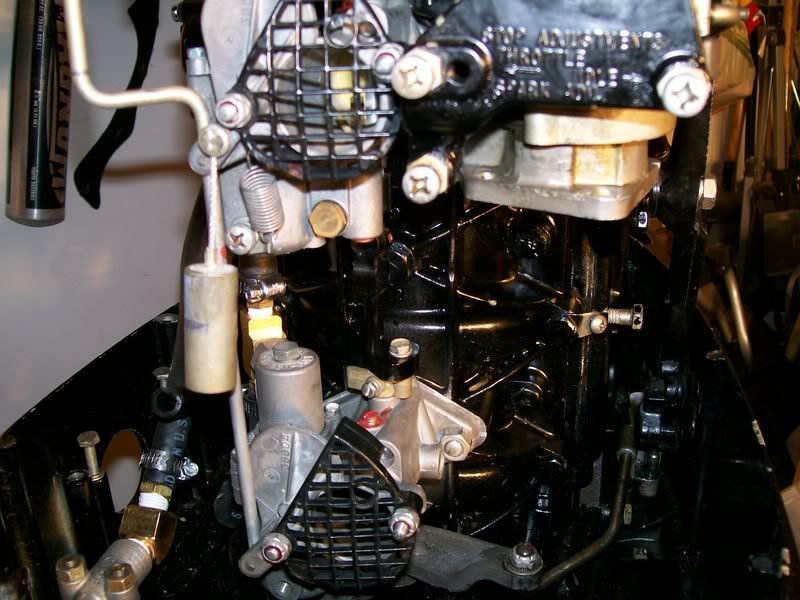

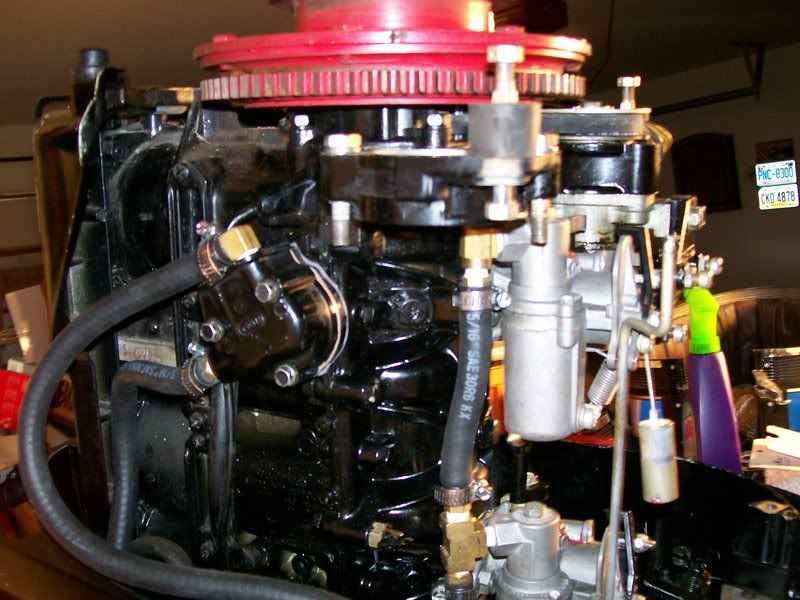

This is a freebie from my Father in Law. 1974 Ebbtide Lakemaster with a 74 Merc 500.

Transom is shot but the floor and stringers are in great shape. Took 2 samples of the foam and it is as dry as a bone down to the keel. I was actually surprised that the floor wasn't a total loss as well due to the fact that the boat was outside sitting for the past 10 years.

The plan is to make sure the motor is good 1st, then proceed with the restoration. I have torn out the transom and as soon as the motor checks out, the top is coming off.

Transom is shot but the floor and stringers are in great shape. Took 2 samples of the foam and it is as dry as a bone down to the keel. I was actually surprised that the floor wasn't a total loss as well due to the fact that the boat was outside sitting for the past 10 years.

The plan is to make sure the motor is good 1st, then proceed with the restoration. I have torn out the transom and as soon as the motor checks out, the top is coming off.