- Joined

- Jul 18, 2011

- Messages

- 18,935

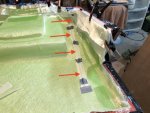

I ran the infusion test last night, doing 3 samples of laminate, peel ply, and flow media combinations as previously mentioned. Resin flow was from the lower part of the picture towards the top (samples were infused laying flat).

.

The best result was sample #2, which had 1 layer of CSM and 1 layer of DBM1708, NO Peel ply but flow media.

Sample #3 was the worst in terms of wet-out. It was similar to sample #2, except it had a second layer of DBM1708.

In between those 2, in terms of quality was sample #1, which had CSM + 1 layer of DBM1708 AND Peel ply.

So, it looks like I'll set up an infusion according to sample #2. The flow media will probably become embedded in the laminate, but that should be OK. (I think )

)

.

The best result was sample #2, which had 1 layer of CSM and 1 layer of DBM1708, NO Peel ply but flow media.

Sample #3 was the worst in terms of wet-out. It was similar to sample #2, except it had a second layer of DBM1708.

In between those 2, in terms of quality was sample #1, which had CSM + 1 layer of DBM1708 AND Peel ply.

So, it looks like I'll set up an infusion according to sample #2. The flow media will probably become embedded in the laminate, but that should be OK. (I think