Re: Carrier A/C, Again!

I know this looks like a monologue but Im sure someone will chime in when they have time... so assuming that the only leaks were actually at the evaporator (which I believe to be true) can someone point me out if this is the right process:

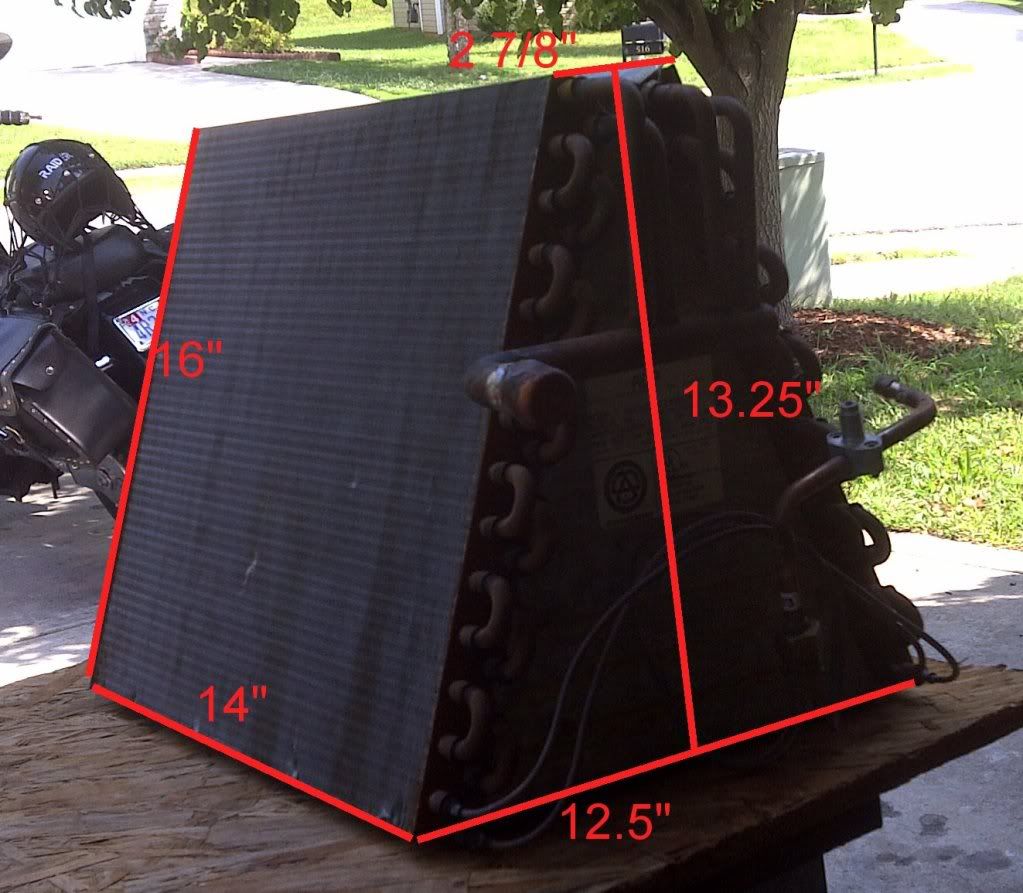

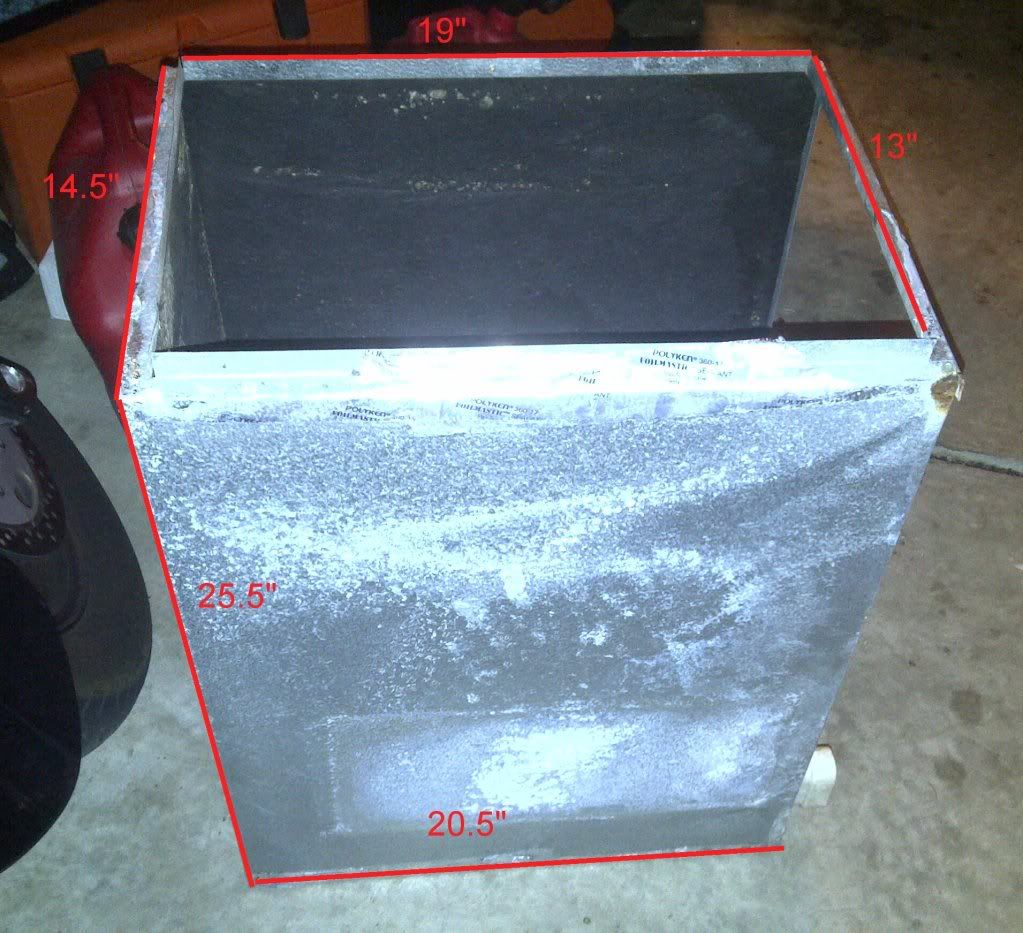

1. Get a compatible evaporator, looking at ebay it seems that they are less than $300.00. (still need to figure out how to find a replacement unit, does it goes by models, size, type?) and braze it in place.

2. Add liquid drier canister (which my system dont have but the neighbors does???) in the high pressure line. About $30.00

3. Vacuum the system (how much or for how long?) with my 2.5 cfm pump, wait 30 min, check if I lost vacuum and if not then vacuum a bit more.

4. Charge the system to the 4.6 lbs noted in the label. About $175.00

5. Cross finger and enjoy 10 more years of trouble free cold air...

Estimated total $505.00

Any one care to fill in the blanks or add to it?

This won't do all the blanks, but may contribute a bit.

My background is working on bigger equipment than home A/C, (and 20 years ago...

) but the principals are the same...some of the components in home units are slightly modified, or one module subbing for several individual components, and/or the piping can be done a bit differently for economy of $$ and space.

All that to say some of my suggestions may not be practical in your situation.

1) Here is a link to get some info re: your evaporator. It will allow you to break down the model number into a set of specifications.

You could also call the company tech support line for homeowners and see what they can offer in further info.

http://www.adpnow.com/wp-content/uploads/2010/10/SG-HAC-28.pdf

2) If you are adding a liquid dryer, for convenience plumb it with a parallel bypass line so that you don't have to shut down to change canister. I have only worked on systems with a canister that contained disposable elements....a bit like many diesel oil filter setups. But I believe many small systems just have an in-line type dryer....if at all. If you do add this feature, in whatever way works for you, there are special "after rebuild" or "major intrusion" filters that you should run as the first and second filter change....and change after Day 1...Day 2 and Week 1.

3) You

CANNOT over evacuate a system. The longer and lower the pumpdown the better. I did a 10 T/Day ice machine compressor rebuild, charged with Nitrogen, pumped down and held vacuum on it for 24 hours. Then recharged with nitrogen...pumped it down again for another 24 hours. That may be overkill, but ANY moisture in a small system is worse than in a larger one....and it is worth going that litle bit extra to try and get a clean system.

4) Not sure what refrigerant you are intending to run, but with a new evaporator, and maybe a new refrigerant, the line capacity may change, too, and your charge amount may also change , so chances are that your TXV may not be in range any more....and may need to be changed out. On larger equipment you can just replace the guts of the valve without having to change the casing...thus no silver soldering req'd.

Not sure what you have on your, system but you should check it out and verify its suitability with your modifications.

Not sure if that helps, but there you go....