Capriupgrade

Seaman Apprentice

- Joined

- Jan 24, 2019

- Messages

- 33

Hi All!

Long time lurker, first time posting. I am excited to try and add some entertaining content to the already amazing amount on iBoats!

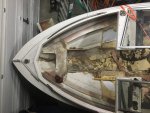

So, back in December I got a wild-haired idea that I wanted to get a boat for my GF (now fiance). One thing led to another and I ended up finding a good score on a 1996 Bayliner Capri 1950 with a rotten deck and low hours 3.0 mercruiser. I took a gamble on this boat as the owner's dad was a mechanic and "appeared" to care for the motor, so worst case I could scrap the boat if it turned out to be too rotten and recoup my investment by selling the motor.

Well...after doing some preliminary dissecting, I determined that this old bayliner was worth saving and is destined to be modernized! (I came to this conclusion after reading a bunch of amazing restorations on iBoat. So, I entirely blame iboats for putting me onto this crazy idea of a boat project! lol). Fast forward 8 months, after doing most of the deconstructing and deck installation, my Fiance suggested we should blog this project. So here we are!

But, before I get everyone caught up on the current state of this project, let me give some background.

About me - I am a native Coloradoan, somewhat new to the boating scene because, you know, Colorado has essentially only ponds. My day job keeps me thoroughly bored peddling paperwork in the pharma industry. When not at work, I have a small fabrication shop (Machning/CNC, welding, wood, etc) crammed in my garage that keeps me busy on occasional contract jobs, but more likely working on the endless list of stuff to fix. Fiberglass is new to me/us, so this is an exciting opportunity to learn a new skill.

About the Boat - It is a 96' Bayliner 1950. It was a fishing boat in Arizona for most of its life and then came out to Colorado around ~2010. It was then parked in this guys yard in 2011 and didn't move/run since. The hull is in good shape, only a few small nicks down to glass on the keel that I will have to repair. The deck was obviously rotten as the ski locker was completely collapsed. Motor looked clean and was properly winterized in 2011, so I took the risk.

The Vision - Going into this, I knew the deck was going to be replaced, which would give me a blank palette to customize to my heart's desire (but within time and monetary limitations or course.). So, first thing first, the back to back mid-ship seats and those cheesy jump seats on either side of the engine cowling must go, cause they are uuuuuuugly. Instead, the back 2-3 feet of the boat will get a 3-peice sun platform over the engine, with gull-wing style hatches on either side of the engine for cooler storage. Next comes a full length 3-person bench in front of the engine, which then makes an "L" down the passenger side. The passenger gets a flip down back to make a lounging area (Just like the newer Bayliners in Tiges). The driver seat will be its own box, with space for a table or cooler between the back bench and it. The driver backrest will also flip forward to allow the driver to face aft while anchored. The bow area will stay the same, but will get some more cup holder options around it. Every square inch will then get gel coated bright white and then EVA foam flooring installed. All seats will get a custom upholstery job with a color theme of off-white, brown, navy blue, and tan, in that order of appearance. A wakeboard tower then tops it all off and I just hope the 3.0 has enough sack to get a board out of the water! lol.

Now, to the first few pictures! (Since this is my first post, I apologize if any of these photos get screwed up). Also, It will probably take a few days to get caught up, because I am pretty far into this already.

Long time lurker, first time posting. I am excited to try and add some entertaining content to the already amazing amount on iBoats!

So, back in December I got a wild-haired idea that I wanted to get a boat for my GF (now fiance). One thing led to another and I ended up finding a good score on a 1996 Bayliner Capri 1950 with a rotten deck and low hours 3.0 mercruiser. I took a gamble on this boat as the owner's dad was a mechanic and "appeared" to care for the motor, so worst case I could scrap the boat if it turned out to be too rotten and recoup my investment by selling the motor.

Well...after doing some preliminary dissecting, I determined that this old bayliner was worth saving and is destined to be modernized! (I came to this conclusion after reading a bunch of amazing restorations on iBoat. So, I entirely blame iboats for putting me onto this crazy idea of a boat project! lol). Fast forward 8 months, after doing most of the deconstructing and deck installation, my Fiance suggested we should blog this project. So here we are!

But, before I get everyone caught up on the current state of this project, let me give some background.

About me - I am a native Coloradoan, somewhat new to the boating scene because, you know, Colorado has essentially only ponds. My day job keeps me thoroughly bored peddling paperwork in the pharma industry. When not at work, I have a small fabrication shop (Machning/CNC, welding, wood, etc) crammed in my garage that keeps me busy on occasional contract jobs, but more likely working on the endless list of stuff to fix. Fiberglass is new to me/us, so this is an exciting opportunity to learn a new skill.

About the Boat - It is a 96' Bayliner 1950. It was a fishing boat in Arizona for most of its life and then came out to Colorado around ~2010. It was then parked in this guys yard in 2011 and didn't move/run since. The hull is in good shape, only a few small nicks down to glass on the keel that I will have to repair. The deck was obviously rotten as the ski locker was completely collapsed. Motor looked clean and was properly winterized in 2011, so I took the risk.

The Vision - Going into this, I knew the deck was going to be replaced, which would give me a blank palette to customize to my heart's desire (but within time and monetary limitations or course.). So, first thing first, the back to back mid-ship seats and those cheesy jump seats on either side of the engine cowling must go, cause they are uuuuuuugly. Instead, the back 2-3 feet of the boat will get a 3-peice sun platform over the engine, with gull-wing style hatches on either side of the engine for cooler storage. Next comes a full length 3-person bench in front of the engine, which then makes an "L" down the passenger side. The passenger gets a flip down back to make a lounging area (Just like the newer Bayliners in Tiges). The driver seat will be its own box, with space for a table or cooler between the back bench and it. The driver backrest will also flip forward to allow the driver to face aft while anchored. The bow area will stay the same, but will get some more cup holder options around it. Every square inch will then get gel coated bright white and then EVA foam flooring installed. All seats will get a custom upholstery job with a color theme of off-white, brown, navy blue, and tan, in that order of appearance. A wakeboard tower then tops it all off and I just hope the 3.0 has enough sack to get a board out of the water! lol.

Now, to the first few pictures! (Since this is my first post, I apologize if any of these photos get screwed up). Also, It will probably take a few days to get caught up, because I am pretty far into this already.