Re: Cabin rebuilt Project

Re: Cabin rebuilt Project

I have done a lot of mold building over the years and Have had both good success and bad failure. Worked in the boat industry for over 35 years at several companies. You have a lot going for you on this project. If your "plug" is really perfect i would suggest dojng this: First if you want a good release spray the PVA first on a very clean surface so it sticks really good several dry coats and a then a wet one to flow it all out. You need a thick layer of PVA. THEN very carefully wax over the PVA. Yes it works I've had good sucess doing this. You do have to wax easily so you don't tear the PVA.

As far as glass finish goes I don't think it matters what you finish with as long as its not WR, lol. With CSM you can easily fill any low spots to help with fairing before you spray gelcoat. I'd suggest that after you finish with fiberglass you get some dyechem metal dye. Dilute it with acetone and rub it all over. Then use long board sanding on the glass and you'll see the low spots very clearly and you can keep sanding or use fairing material or a high build primer to fill those low spots. Durateck (fourseal?)makes some really great polyester primers that sand easily and make fairing a breeze. Remember that a good gelcoat thickness is only 18 to 20 mills and your substrate has to be better than that or you will sand through it, just sayin. No matter how you do it if you want a gelcoat surface your in for a lot of wet sanding and buffing doing it backwards. Making a mold from your plug and then a part from the mold doesn't make sense to me for a "one off" like your doing.

Ahhh having that much experience would certainly come in real handy ! This was a great learning experience for me. Still a lot to learn in order to see this project to the end. I think you just solved my dilemma, I really didnt want to sand FG on the final layer (if I did moldless form), but now it looks like I dont have to. I could just use polyester primer to fill the weave than just sand the primer down ye?

Following was my plan, please tell me if this is a good way to go about doing it, and if you would/wouldnt do it this way.

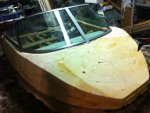

If you look at the last photo you can see that my plug comes in 2 parts. One is the foam bit and the other is the plywood laminate.

Now, to get the best finish I thought on what if I drop 4 layers of 20oz cloth over the whole thing than 1 layer of really fine cloth to get a smoother finish than sand it down flat (this part I was dreading) but now I could just fill the weave with a primer than sand the primer flat and ready for gelcoat.

After laying the final cloth layer I would pull out the foam plug, prepare and fiberglass the inside of the previously layed layers. This leaves me with sandwiched plywood leminate.

I thought id do it this way so that I can have a smooth top layer (minimize sanding), right thickness and sandwiched plywood. Also cant do too many layers on the outside otherwise ill lose the windscreen channel and it wont fit.

Does this make sense, its a little late here ? Thanks