ChristianG

Cadet

- Joined

- Sep 7, 2023

- Messages

- 10

Hi guys.

My name is Christian and I am from Copenhagen in Denmark.

This is my first post in this forum.

I am working on a 15 square meter solar cell driven Catamaran and are now about to assemble the 2 pontoons to the bottom plate that are connecting the two pontoons.

The bottom plate is a 40 mm thick sandwich construction with XPS foam in the middle and 1.4 mm glassfiber on each side of the XPS foam.

I am doing all the work myself and it went quite well - untill today.

Now I desperately need the help from your community.

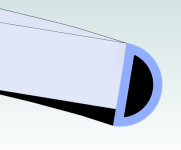

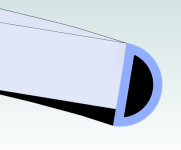

I made a test where I glued a 50 mm high D-shaped fender list on a 40 mm test glassfiber mock up, with Sika 591, at let it dry for 1 week - See screencapture from 3D model below.

It was highly recommended in several forums for gluing rubber on glassfiber, so I expected, that my small test would show, that everything would work perfect.

BIG BUMMER!!!

The Sika 591 stuck perfectly to the glassfiber, but I could peel off the rubber from the Sika 591 with only a force of about 200 grams!!

The rubber is something, that is a little "foamy" with a thicness of about 6mm and because it has been rolled up for many years, she straight part of the D profile is convex with about 5 mm as well - meaning, it is impossible to press the D-profile in against the side of the bottomplate.

So there is many issues here,

I COULD plug the ends of the D-profile and fill it with a little air while it is glued in place in order to make the D-profile straight again.

Questions:

1. What would you do in my situation?

2. Can you recommend a glue, that can stick on rubber and work for at least 25 years? some 3M product

3. I work with epoxy for all the glassfiber work I do on the boat. Is the solution as simple as using wpoxy and filler?

4. Do you recommend using the tedious and annoying work to place a LOT of threaded nuts and attach the fender list with bolts?

In the hope to get to learn from your experience,

Christian

My name is Christian and I am from Copenhagen in Denmark.

This is my first post in this forum.

I am working on a 15 square meter solar cell driven Catamaran and are now about to assemble the 2 pontoons to the bottom plate that are connecting the two pontoons.

The bottom plate is a 40 mm thick sandwich construction with XPS foam in the middle and 1.4 mm glassfiber on each side of the XPS foam.

I am doing all the work myself and it went quite well - untill today.

Now I desperately need the help from your community.

I made a test where I glued a 50 mm high D-shaped fender list on a 40 mm test glassfiber mock up, with Sika 591, at let it dry for 1 week - See screencapture from 3D model below.

It was highly recommended in several forums for gluing rubber on glassfiber, so I expected, that my small test would show, that everything would work perfect.

BIG BUMMER!!!

The Sika 591 stuck perfectly to the glassfiber, but I could peel off the rubber from the Sika 591 with only a force of about 200 grams!!

The rubber is something, that is a little "foamy" with a thicness of about 6mm and because it has been rolled up for many years, she straight part of the D profile is convex with about 5 mm as well - meaning, it is impossible to press the D-profile in against the side of the bottomplate.

So there is many issues here,

I COULD plug the ends of the D-profile and fill it with a little air while it is glued in place in order to make the D-profile straight again.

Questions:

1. What would you do in my situation?

2. Can you recommend a glue, that can stick on rubber and work for at least 25 years? some 3M product

3. I work with epoxy for all the glassfiber work I do on the boat. Is the solution as simple as using wpoxy and filler?

4. Do you recommend using the tedious and annoying work to place a LOT of threaded nuts and attach the fender list with bolts?

In the hope to get to learn from your experience,

Christian