AShipShow

Lieutenant Commander

- Joined

- Jul 8, 2016

- Messages

- 1,803

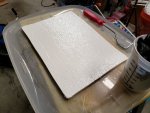

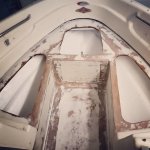

I had another thought that might be worth trying... I read somewhere that you can mix gelcoat with poly resin and it will result in a lower viscosity liquid... Wondering if I do that, plus add like 5% MEK, I might get something that will flow out enough and not cost me any money since I already have that stuff. Maybe I'll make a test panel and give it a shot to see how it levels and cures. I could even add some white pigment to the laminating resin to help with the opacity... Then for my final topcoat, I can use plan gelcoat that is color matched to the hull, and maybe I can use duratec for the last coat...

I don't really want to go the route of patchaid or duratec for the whole thing, because for one, it isn't cheap. Also, it causes the gel to air cure which means I would have to sand between each coat and I plan on 2 to 3 coats. I'm thinking if I can get the first 2 coats to lay down and level out fairly well, then maybe I can use duratec for the final coat to thin it, and give me the air cure benefit...

I don't really want to go the route of patchaid or duratec for the whole thing, because for one, it isn't cheap. Also, it causes the gel to air cure which means I would have to sand between each coat and I plan on 2 to 3 coats. I'm thinking if I can get the first 2 coats to lay down and level out fairly well, then maybe I can use duratec for the final coat to thin it, and give me the air cure benefit...