Re: 77 Skeeter Wrangler restoration

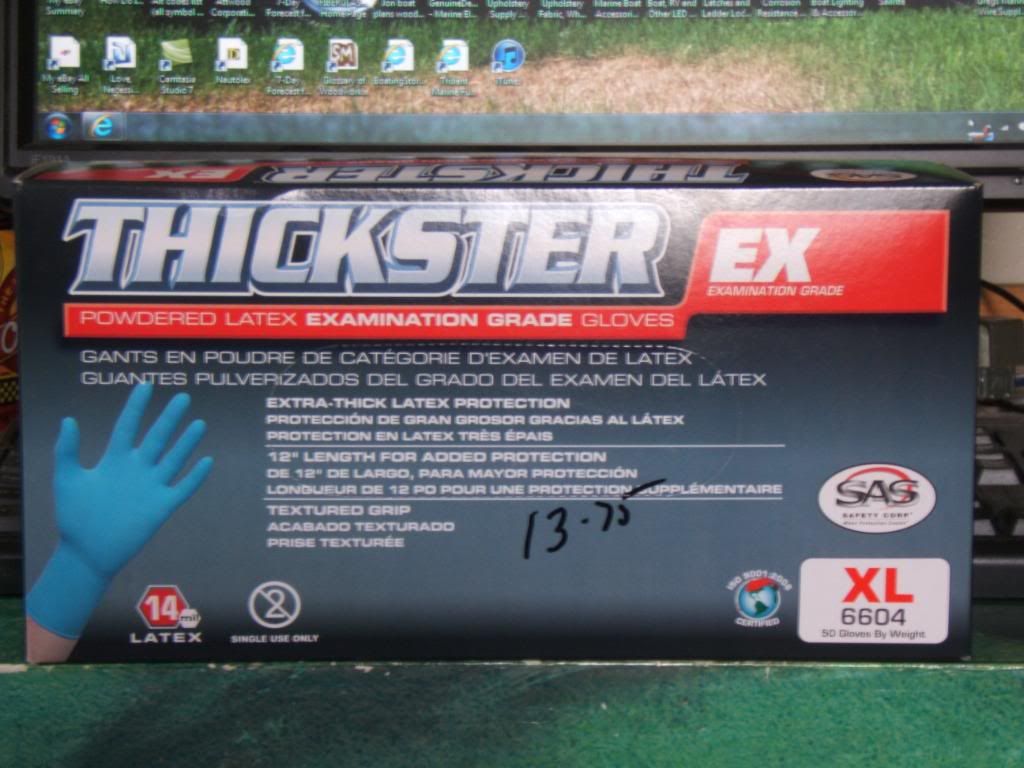

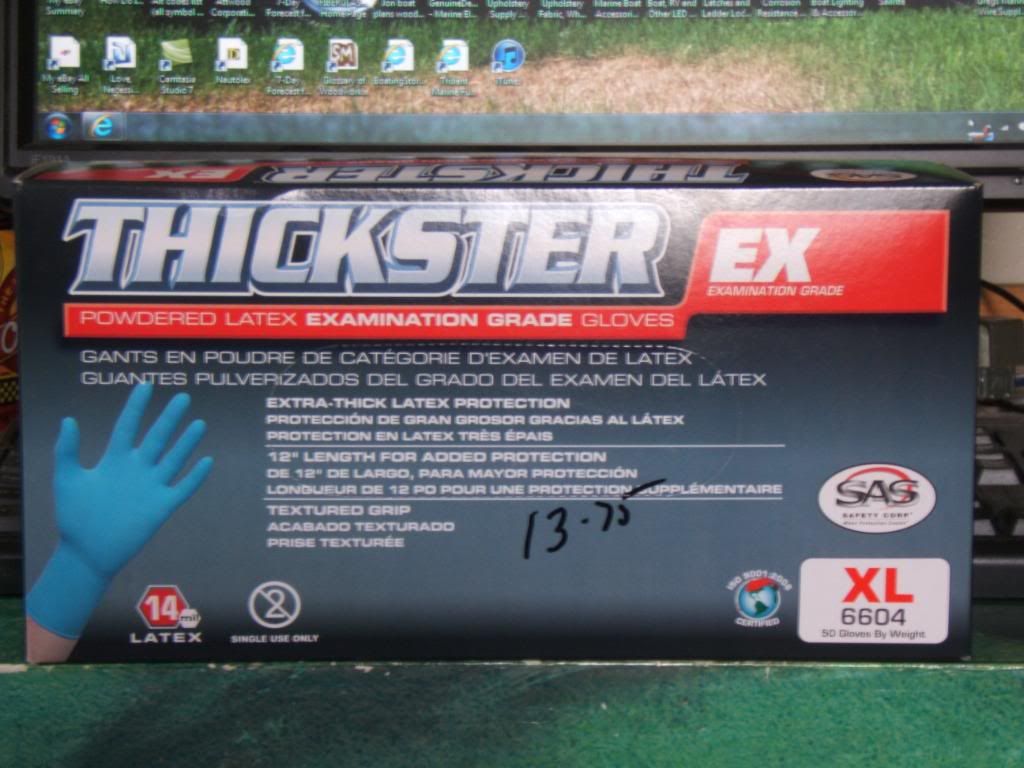

Get the Thickster gloves, 14 mils thick and they hold up really well...heard say you can use Playtex gloves also...Box says single use only...NOT, if they don't tear, I have gotten several uses out of a pair...you get approximately 25 pair per box...

Unless you plan to do a lot of throw away, and this is a trade off, you will need lots of either acetone or lacquer thinner for clean ups...

If you are resourceful, you can reuse the dirty clean up solvent by letting it sit in a closed metal/plastic container for a couple of days to let the grunge settle out of it and reuse it...

I say its a trade off because the solvents are NOT cheap, but they do let you reuse things like brushes and buckets many times over, although the cost of new brushes and buckets may be cheaper in the long run...

Baby powder is your friend...buy the big bottles at the discount pharmacy store...it helps in so many ways...before you put on your PPE, makes your gloves slide on easier, while working, you get your gloves all hairy, wash them off with solvent, they will become sticky as heck until you powder them up, if you clean up your brushes you can give them a dousing of powder to keep the brush reusable [BTW, you will still have to "soften" the bristles in some solvent before reuse, as they do become stiff], If you clean your mixing buckets and stack them into each other, after they dry, give them a dusting to keep them from sticking together...etc, etc...

Bubble buster roller...

Plastic Spreaders...a.k.a. bondo spreaders...

Some way to measure your MEK-P...I use pippetes graduated in ML's and they measure up to 3ml...

Scrounge up some cardboard to use as wet out place mats...put your cardboard on the table, wet out your mat/cloth, then carry the wet out piece to the work area...helps to make the cloth lay better when its pre-wet...

Rags for constant clean up while applying lams...keep a couple of wet ones in solvent...they are somewhat reusable if you wring them out after use...they will become hard and stiff, but a bit of soaking in solvent before the next session of glassing will usually soften them up enough for some more use...

That's all I got for now...

gt