Pusher

Lieutenant

- Joined

- Sep 2, 2014

- Messages

- 1,273

Stern Eye hooks in! And yes, it was as miserable as we thought it would be. Key to not blowing out the plywood on the other side is to put a block of plywood over it. It'll prevent the epoxy from exploding on the back side. This really is a 2 man job.

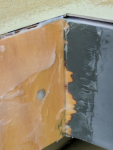

Close up. 5200 on EVERY surface.

Nice. Some holes from the previous owner had corroded badly because they used a vinyl or nylon washer. Guys, do NOT use a plastic between stainless hardware and aluminum.

We added those 2 pieces to Prevent drilling into the transom.

Good call. Since you mentioned it, have you looked into your pitot and transducer connection on the outside transom yet. I 5200'ed Teflon cutting board onto my white transom but WM's aluminum setup might look better on your hull.