Mark72233

Ensign

- Joined

- Jul 11, 2014

- Messages

- 926

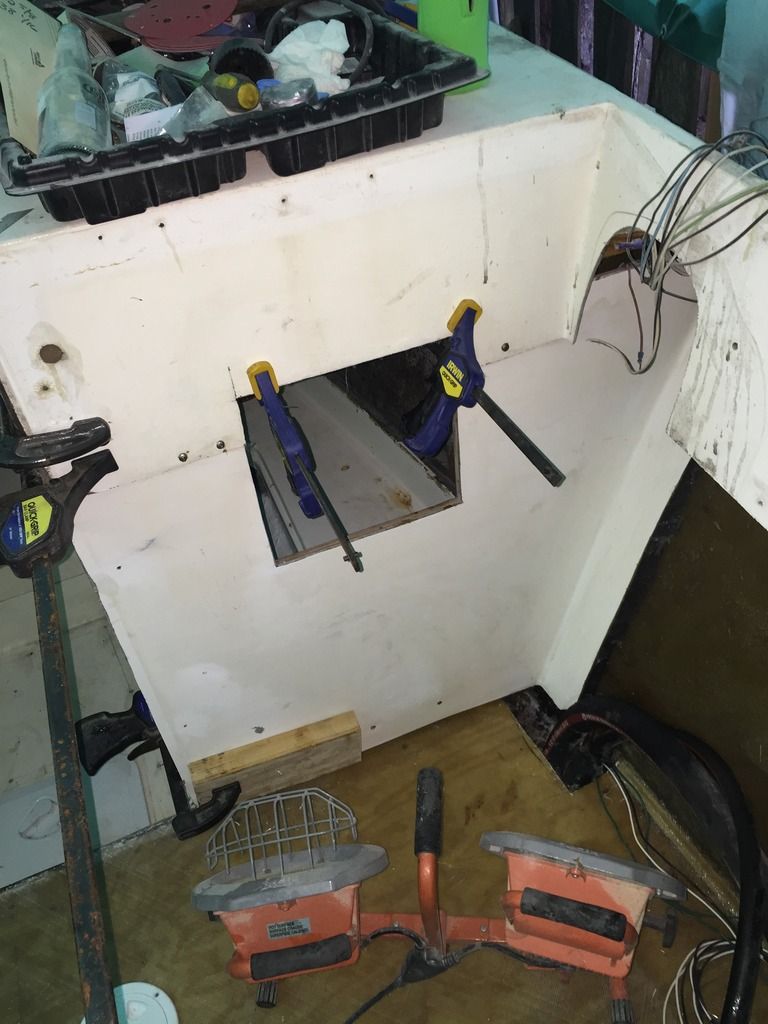

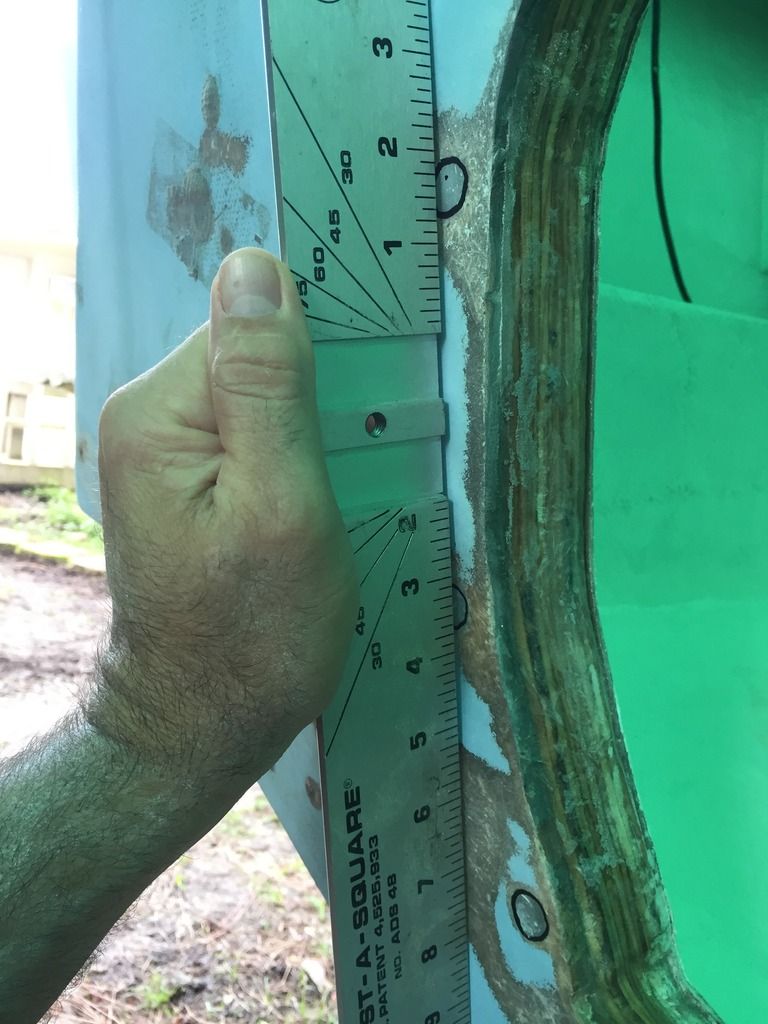

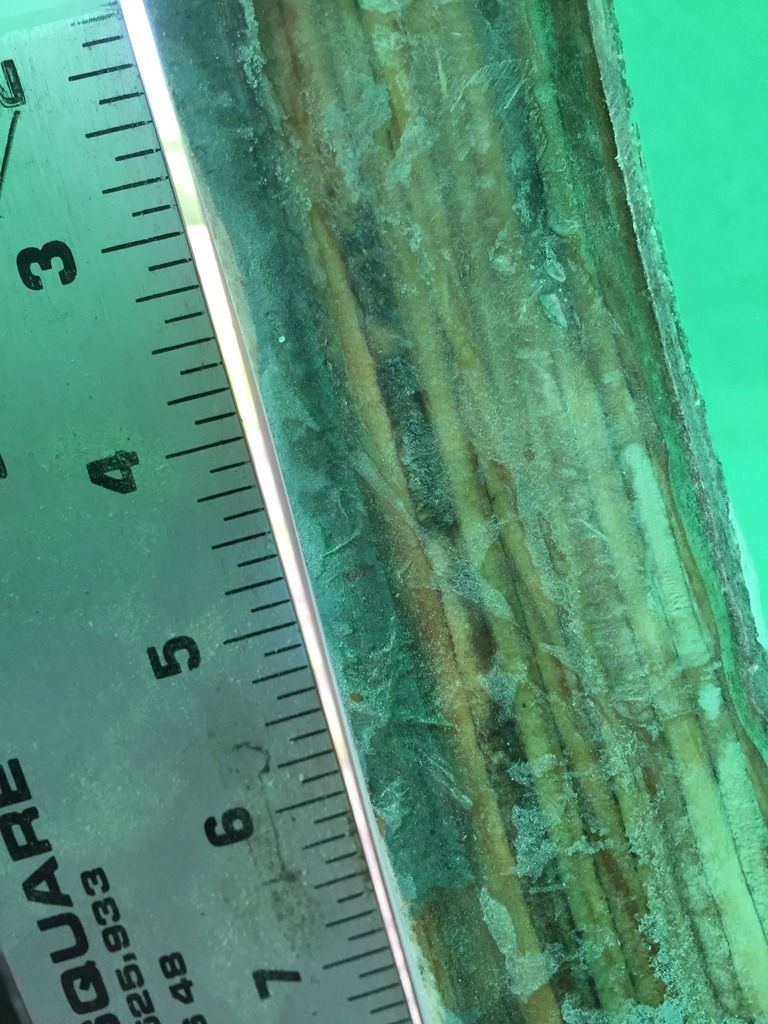

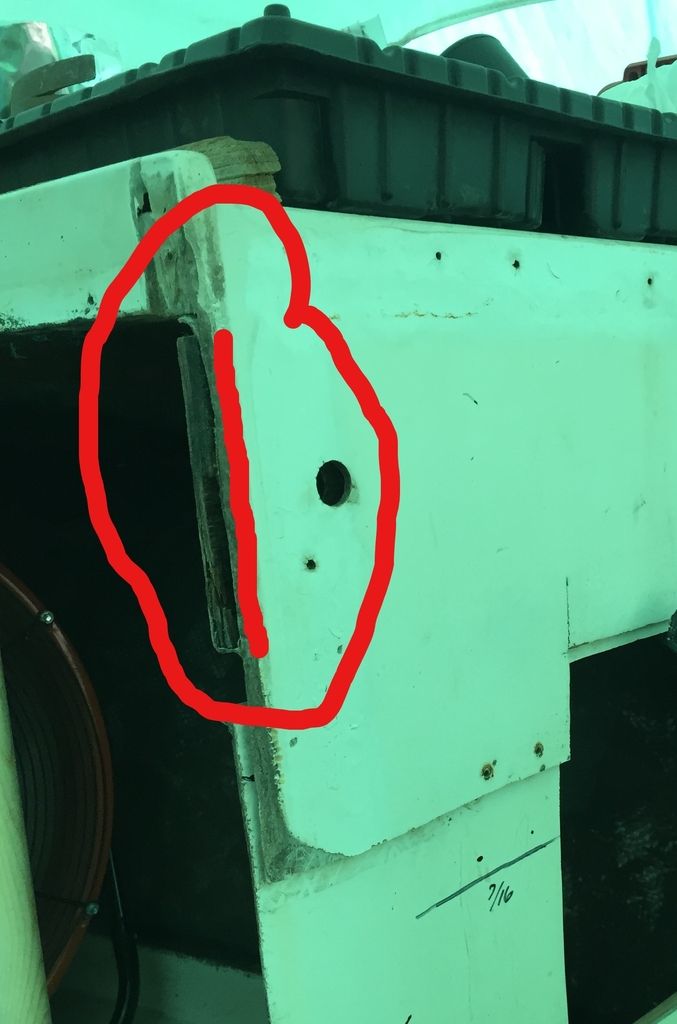

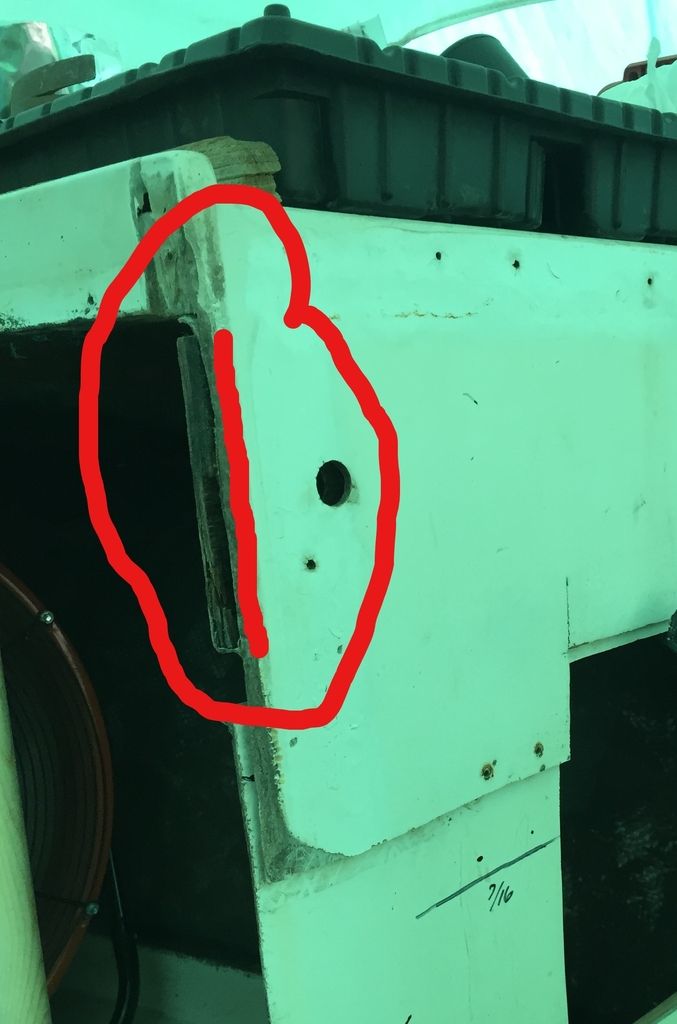

This is the back side of the starboard panel as you go into the cabin. The picture is from the tear down time frame. Anyway, where the red line is at is where the panel is fiber glassed to the cap section right behind and under the console. The top part is also backed by a piece of 1/2 plywood that at water damage so that also had to be removed on both port & star.

Its kind of nice working on something besides stringers, bulkheads or decks.

Its kind of nice working on something besides stringers, bulkheads or decks.