Weekend update:

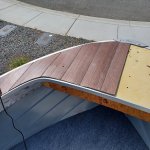

I installed my digital tach/cylinder heat temp gauge, the wires were too short to run from outboard to dash, luckily the temp sensor is an rtd, not a thermocouple, so I was able to splice in extension wires. I mounted my floor locker with hinges, I'll probably change the trim from 3/4 beveled wood to 3/16 aluminum or similar when I start working on it again. I'll leave the seat covers and drawers uninstalled for now, they aren't urgent. I emptied last years gas into my car to dilute and burn off, then ran some fresh gas with concentrated seafoam and injector/carb cleaner through the engine. There is an issue where it will idle for awhile and shut off. It restarts right away and with how long it can run, I don't think it is a fuel pump/choked flow problem. My best guess is some air possibly getting in through a loose connection. Once that's fixed, I'm going to run as is for the season so I can actually fish.

Next winters work:

-I decided the center opening in the bow doesn't matter to me, so I will make a solid platform there that runs to the back of the console sides. I think this will simplify bow storage as well.

-I have a plexiglass pane to make a windshield center, but am now thinking I will just replace the whole windshield with something custom. I'd like to use tempered glass but I may cheap out and stick with plexi. The plan will be to make an angle aluminum frame, probably windshield wipers if I go with glass. Seriously contemplating getting a tig welder for the aluminum work I want to do.

-finish drawers/seat covers/locks and latches.

-I will likely paint my gunnel, thinking durabak. I think long term I won't be happy with foam.

-remake dash, give it a decorative face, make a glove box for the passenger side

Things that will slowly happen this summer:

-better anchor mount/possible caddy

-trailer mods

-better lighting and battery switch