benfish909

Petty Officer 2nd Class

- Joined

- Jan 4, 2021

- Messages

- 122

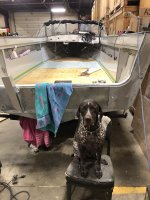

Thank you. Now I really want to paint the outsideLooks good! Ill be happy if mine turns out like that!!

Thank you. Now I really want to paint the outsideLooks good! Ill be happy if mine turns out like that!!

I have been trying to figure out the search function but can't get it to work well. I would think if you used large enough wire the distance wouldn't effect it too much but electrical knowledge is limited. Say use some tin copper 2/0 wire for a 90hp motor or would there still be significance volt drop. I didn't even think about the extra physical abuse from being in the bow. Now I'm thinking keep it simple and keep them in the transom area.There are plenty of posts and advice about keeping your starter battery close to the motor. Harder to start the farther away it is. So far Im planning on putting one up front and one in the rear. My starter/bilge in the rear, lights/radio/FF in the front. Not wired together.

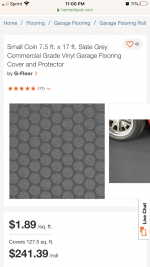

As a side not I think I am going to move the batteries to under the bow to move some weight forward and I already have to reword everything. Wanted to see if anyone had and thoughts on pros or cons. Also looking at marine vinyl adhesive, it looks like I should use a solvent based adhesive like MD-102 since my floor will be sealed with epoxy. It is pricey And wanted to see what others have used.

I ended up on deciding to do hydro turf for the little storage shelf’s and up the gunwale bc I would have had to order another 9’ of vinyl and the hydro turf is cheaper and easier to install. I won’t have any mechanical fasteners holding the flooring down except the seat bases. May just bite the bullet and get the expensive solvent based glue but wanted to see others results with using the stuff from big box stores.Our boat is 5 ft shorter so it was a bigger impact, but I have my two house batteries up under the front seating area and my starter back by the motor. As others have said, the long run for a properly sized wire will cost but can be done.

I used 3M 90 Spray Adhesive. Worked well for my floors and seats, as they had mechanical fastener as well. Not so much when it was the only thing holding it on on the sides of the hull.... I eventually went to some exterior vinyl adhesive from the big box store. It did better, but again the aluminum was a hard surface to adhere too. That being said, if you really want to make sure it sticks save the last coat of epoxy for in the boat and use it to adhere the vinyl. Don't think you will ever have an issue with it come up then.

SHSU

If you read some of the old threads, a lot have used the exterior Big Box store glue for vinyl. As long as your comfortable with it, that is all that mattersI ended up on deciding to do hydro turf for the little storage shelf’s and up the gunwale bc I would have had to order another 9’ of vinyl and the hydro turf is cheaper and easier to install. I won’t have any mechanical fasteners holding the flooring down except the seat bases. May just bite the bullet and get the expensive solvent based glue but wanted to see others results with using the stuff from big box stores.

I thought about using the last coat of epoxy as glue but worried about it just cracking instead of flexing like an adhesive

Very nice!!!

I know I shouldn't ask, but why does one set of bolts have washers and the others don't?

I noticed that in the picture too. Oops. I get in a rush when covered in 5200. Not sure why, it takes a week to dry lolSHSU

lolI noticed that in the picture too. Oops. I get in a rush when covered in 5200. Not sure why, it takes a week to dry lol

Thanks. It might be a touch too high but can just cut it down if needed. We will see when the motor get mountedLooking good

That bracket is looking really nice.

SHSU