Lou C

Supreme Mariner

- Joined

- Nov 10, 2002

- Messages

- 13,899

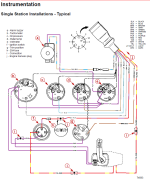

On the ignition switch:Thanks, I don't know how the dashboard is wired up but it occurred to me that if the ign on wire connects to the ign switch at the front of the boat (as opposed to coming from a relay at the rear), then if the ignition switch gets power from the same wire that runs to the front to power other stuff like lights etc any voltage drop on that wire would result in the batteries getting too much charge... Hence my question about running a separate wire from Vsens on the alt direct to the battery isolator switch.

S terminal being the unswitched starter terminal?

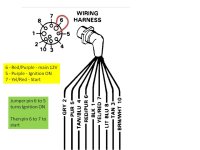

terminals:

B=battery, red wire should show battery voltage when battery switch is on

I=ignition, purple wire should show battery voltage when key is turned to ignition on (1st notch from off)

S=start, yellow red wire, this should get battery voltage when you turn it to start.

that same yellow red wire runs to a relay on the engine somewhere and then down to the S terminal on the solenoid.