kcassells

Fleet Admiral

- Joined

- Oct 16, 2012

- Messages

- 8,741

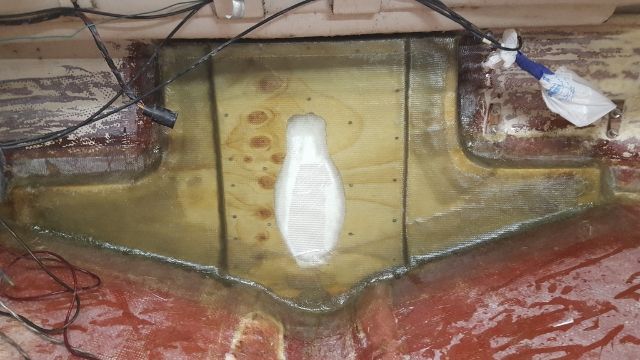

Well I might have let my nerves get the best of me with that last post. I think I did mix it to light but it finally got pretty tacky. So I tipped it up and put down some more resin, then laid down the CSM. Went pretty well I think, seem to get a bunch of small bubbles between the CSM and resin but the bubble buster did its job. I can see how hard it would be to wrap around edge once I got to the edges.

I also tried my hand at some PB, went well I think. I'm glad I got the big bucket of Cabosil. I was smart about it and after I was done with the resin on the CSM I quick mixed in some cabosil and chopped strand so I didn't waist any resin. I then spread more on the areas I need to blend in on the side walls. So far I only waisted about 8oz from the first batch before I thought about using it on the side walls.

One final question for the night on the PB, is the cabosil just to thicken it enough so it stays where you want? Or does it serve any strength purpose? I only ask because the first batch I used not as much cabosil and still was able to shape it nicely and have it stay in place.

The cabosil is your waterproof thickner. No strength.

http://fx.wikia.com/wiki/Cabosil