saltchuckmatt

Captain

- Joined

- Jul 19, 2019

- Messages

- 3,126

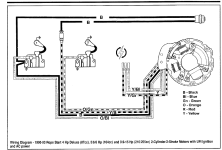

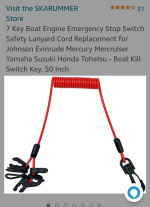

Yes, the switch completes the grounding. (Normally open) so when you pulled the wire apart you stopped the grounding. Your switch is not releasing. You could try wd40 and pushing it a bunch of times but switch is a common failure.So you think it's the switch, rather than a loose connection?

See my video I just posted. I don't see a telltale, but not 100% what I'm looking for since the water flow schematic shows it from the side only.

Water is coming out the exhaust relief holes so that's good but not an indication of whether you are getting enough. I would pull the foot, check or replace the pump and grease the driveshaft. Pretty easy to do and well worth it.

Expect a rash of comments about having not having enough of your motor in the water.