Update 01-07-2010 later that evening

Update 01-07-2010 later that evening

Stopped by Yatch Dr's work on the way home yoday and picked up the gel. He had already tinted gel from spectrum, no need for the chip. And he gave one of the best classes I ever had. He knows his stuff and was able to talk the chemicals and the various techniques of all this stuff and all the product associated with fiberglass. He blew my mind away!

I deffinately did not retain half of what he taught me but I'm going to try to do it tonight to help it strick in my head.

By the way Yacht Dr. Got home safe and sound, but only took me 2 hrs for 25 mile drive. At least no accidents! Thanks Again. Like I said I'll be back in a couple of months to get some grey tinted up and another lession. I also left that pt of Michigan Fiberglass liquid gel. Hope you can use it.

Proshade tree this is going to be a new boat when its done with Yatch Dr's schooling! Migth never leave the driveway. To nice for the water........

Anyways, Since I have been home I dove right in to it!. Let me start off on what Yatch Dr. taught me, I want to say the few things. Deffinately need a full vapour mask for this job. This stuff is way toxic. Also If you have facial hair, you either need to shave shave it off or use vasilne for a perfect seal to the mask. I'm feeling it after 1 hr with no seal but with mask. Will be finding the jar of vasilne before I go back out. Second This is not hard to do, just need to know the proper steps and not to worry about screwing up. You can always grind it out and start over. No for the repair.......

Here is the two holes up close that got pulled through. They ripped the glass when I found out my transom was rotten. One of the first indicators I had to the transom problem. I have already laminated on the other side with 1 layer of 1708 and epoxy. Look back a couple of pages and you will see that process and how I got here. Here is the holes are before washing the area a couple of days ago.

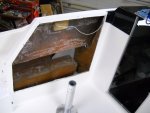

Here is top view of the same holes tonight before I started. See how deep they where. I need to build this back up before gelling. Along with feathering the area out for the new gel.

I first started not like Yatch Dr. told me, sorry!, he told me to sand the whole area that will get the gell repair with 180-220 grit first. Then grind the dish out. I ground the area out first to find out how big the dish was going to be with my rotory grinder and 36grit disc. Here is the pic.

Then I sanded out anouth 2-4" for the gell repair feather. With the 180 sand paper. This is to make the gel low for the new stuff when I feather it and make it flat, but also to clean the surface and make the surface ready for the mechanical bond. Here is the out come.

Next post....

( not to say he wasnt before..but..oh you know what I mean lol ).

( not to say he wasnt before..but..oh you know what I mean lol ). .. but Im having one now with for ya m8

.. but Im having one now with for ya m8  .

.