So exactly what is wrong with the old stator? Was it burnt? Or could it just be a broken wire that can be repaired with a soldering iron? As mentioned, the original has 6 wires. But take note two yellow wires are twisted together and two blue (brown blue) wires are twisted together and only connects to two terminals. The other two yellow wires connects to the rectifier which is the charging circuit of the stator. Remember the stator serves two functions, first as power source for the ignition system and second, as a charging unit for the battery.

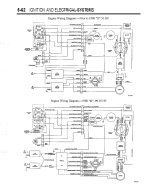

There are many stator on ebay that fits your 50 HP motor. But most of them only has 4 wires, i.e. green, white and 2 yellows. The yellow wires goes to the rectifier while the green and white goes to the terminal for the module or power pack. Others have 6 wires with two blue and two red and two yellows. Again, with this wiring configuration, the two reds connect together to one terminal of the power pack module and the two blue does the same. The two yellow still connects to the rectifier. You can also just connect one red and one blue to the power pack module and just tape off the remaining blue and red wires. In fact, if you put an ohmmeter between the two red wires you'll get zero ohms as these two wires are connected together internally and the same is true with the two blue wires. Here's the wiring diagram for your "D"

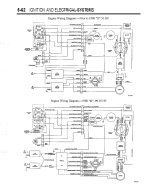

50 HP. If you have the Green, Green and Blue, Blue stator then your motor must be a 1987 or 1988 50HP prior to the "D" wiring. Anyways, the four wire stator or 6 wire stator will still work as explained above. Remember the two yellow wires connects to the rectifier.