GA_Boater

Honorary Moderator Emeritus

- Joined

- May 24, 2011

- Messages

- 49,038

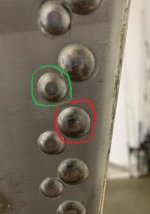

Some times Starcraft boat "technicians" weren't very concerned about drilling holes and rivet placement. I have a few almost overlapped rivets with the factory blue paint, the same color as my tinnie in my signature. Ooooops, sig pics aren't working yet, so take my word for it.

But none of my stuff looks like yours. Except the PO damaged stuff. That guy gets around!

But none of my stuff looks like yours. Except the PO damaged stuff. That guy gets around!