Okay, I have a transom design question. Regarding the area shown in red here, this is where the transom was, just in this center portion of the rear.

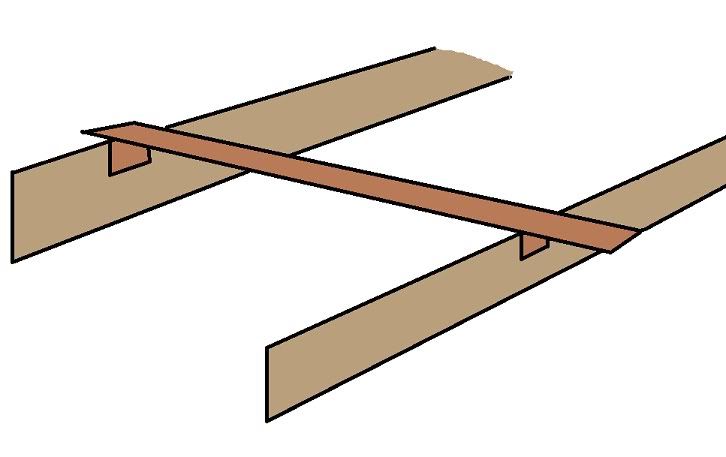

I'd like to have the transom extend the width of the aft of the boat, however I have the issue shown below (overhead view):

The center portion is more or less straight, and the other 2/3rds are at an angle. I was thinking I mount, PB, and tab the center portion, fiberglass it into place, then add wood at the same thickness to the other two portions, and put a ton of epoxy PB at the triangle shaped void between the portions of wood (unless I can get the wood cut at such an angle to fill that little void) then tab and glass those side portions in the best I can, I'm worried that the side 2/3rd portion of the "transom" would be subject to flex, is that unreasonable? Need I even worry?

It is. However, very heavy and kinda PRICEY!!!

It will hold up quite well.

You ain't kidding! Not cheap... Good thing I only needed the two boards...