@SHSU Thanks! Just got the transom completely drilled out today and cleaned out the boat for its bath tomorrow.

For the fuel tank, I need to keep it as low as possible since I only have a few inches of clearance on top. All the supports and base plate will be made from the same 1/8” AL sheet that Ive used for the rest of the project. Right now im thinking of using a sheet cut to the size of the bottom of the fuel tank, with a middle support underneath tied into the ribs for support. This main support sheet under it would have strips of neoprene for it to rest on. Then brackets along the front and rear holding it from sliding, also padded with neoprene, and straps holding it down. Should allow me to remove it then if needed too. The gas tank supports and installation will come after paint and half the decks/foam being installed, up to the consoles.

Not sure if anyone noticed, but plans did change when it came to reinforcing the hull. I mainly focused on the gunnels knowing i walk on them and will have downriggers attached. My chine rivets were all perfect and I put her through abuse last year with most of her structure compromised so im not sweating skipping that part. I believe big water and bigger boats are more subject to failure there, or user error being in water beyond the boat’s capabilities. I will still tie the gunnel wood and deck together, and reinforce a lot of other above deck areas, hopefully acting like a lesser version of chine reinforcement. If i do run into issues then there will just another tear down and rebuild... I recently went through your build again

@SHSU and I dont believe you did any chine reinforcement, so unless i missed something, that was part of my decision not to do that extra work. Also the interest of time... i would have been set back a few weeks to get that done.

Steps before paint:

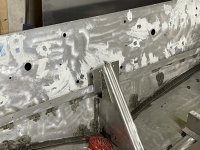

Starting tomorrow I will get the boat washed and prepped for the putty to fill holes. Lots of PO mounting holes to fill... Will also do a second round of coat-it to cover a few rivets I missed and some holes getting the putty.

After that its foam and decks! If Im lucky I will get that done before the weekend. My deck wood is already sealed so its mainly foam and then making sure the decks are sealed to my standards. Some holes in the deck need filling from where I took out the PO’s screws that held it in before. Its all new 3/4” cdx and was epoxied so im feeling good about that install coming up!