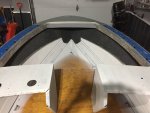

Managed to get some vinyl laid down on the gunnel tops. Was just going to get it all cut a prepped, but I couldn't bring myself to call it a night

. My garage is sitting around 50 degrees, so a little cooler than ideal, but with all the warnings all over the contact cement can, I didn't really feel like cranking up the heat. Glad I had the respirator on hand or it would have been a party in there with all the fumes. Went down pretty well with a few little issues from wrinkles due to the width of the vinyl being a tad less than the beam of the hull. Had to make a few slits to get it all to lay flat, but they should go unnoticed when all is said and done. I had cut the floor of the Nova out of the center of the vinyl with the knowledge that the remaining edges would be used for these gunnel tops. worked like a champ, just a bit of a dance trying to lay it out and glue it down as a one man operation. I loaded some boards on top and will give it a day or two to dry before messing with it further. I had hoped to paint the gunnel sides 1st, but my paint still has yet to ship and I figure any edge overlap will be covered by the trim anyhow.

I think all the waiting between sealing, painting, drying, etc. has come to be my least favorite part of these projects. Another day in the books. Hope for an opportunity for more progress tomorrow.

Cheers!