BWR1953

Admiral

- Joined

- Jan 23, 2009

- Messages

- 6,525

However, I do know how to use parallel processing!

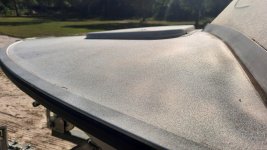

Took the Chief to the dustless blasting guy on 15 Apr 22. He said there were 3 other boats ahead of me but that he'd try to squeeze me in later this week. Then he called me this morning to say that the Chief was done and ready for pickup! Alas, no pix of the blasting process because I didn't know it was happening.

But, I managed to pick it up this afternoon before picking up the sod.

I'm very pleased with how it turned out!

I managed to get the Chief home just in time to go pick up the boy from school and then we went to pick up the sod. So, no actual Chief work by us today. But soon... I do have several other projects which require my attention before I can get deep into the Chief. Gonna try some parallel stuff again too.

Back in our own backyard.

I'd forgotten to bring the splashwell with the Chief last week but brought it this morning. It was blasted while I went to the bank to fetch money.

Took the Chief to the dustless blasting guy on 15 Apr 22. He said there were 3 other boats ahead of me but that he'd try to squeeze me in later this week. Then he called me this morning to say that the Chief was done and ready for pickup! Alas, no pix of the blasting process because I didn't know it was happening.

But, I managed to pick it up this afternoon before picking up the sod.

I'm very pleased with how it turned out!

I managed to get the Chief home just in time to go pick up the boy from school and then we went to pick up the sod. So, no actual Chief work by us today. But soon... I do have several other projects which require my attention before I can get deep into the Chief. Gonna try some parallel stuff again too.

Back in our own backyard.

I'd forgotten to bring the splashwell with the Chief last week but brought it this morning. It was blasted while I went to the bank to fetch money.