Crankerbait

Seaman Apprentice

- Joined

- Nov 5, 2021

- Messages

- 31

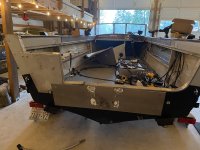

I am starting a project of a recent purchase on a 21’ 1974 Starcraft Holiday. A little back story, I purchased this boat a few months back. The PO told me he had gone through and replace ALL rivets about 9 years ago. He had the bottom of the boat Rhino lined (similar to flex seal or a truck bed liner). The boat has a nearly new 115 Evinrude E-TEC and 9.9 Suzuki kicker.

Now the issues,

While doing some maintenance I found the knee brace was was damage after what looked like a pretty poor previous repair, the Splashwell had been previously welded in a couple spots but was showing stress and cracking again. The transom was also replace 9 years ago and was in good but not great shape.

I started to dismantle things and some of my fears were confirmed when I discovered the Rhino lining was trapping moisture between the lining and the aluminum causing corrosion. I’m still in a deconstruction phase to determine how bad things are and how much this project will require.

My plan is to remove the rhino lining, clean, repair and paint the hull, rebuild the transom likely with a new shape and splashwell. I’ll also consider adding extra supports throughout the boat, not really sure about what is necessary.

Anyway follow along if you like. I’ll attach photos of where I’m at now.

Now the issues,

While doing some maintenance I found the knee brace was was damage after what looked like a pretty poor previous repair, the Splashwell had been previously welded in a couple spots but was showing stress and cracking again. The transom was also replace 9 years ago and was in good but not great shape.

I started to dismantle things and some of my fears were confirmed when I discovered the Rhino lining was trapping moisture between the lining and the aluminum causing corrosion. I’m still in a deconstruction phase to determine how bad things are and how much this project will require.

My plan is to remove the rhino lining, clean, repair and paint the hull, rebuild the transom likely with a new shape and splashwell. I’ll also consider adding extra supports throughout the boat, not really sure about what is necessary.

Anyway follow along if you like. I’ll attach photos of where I’m at now.

Attachments

-

31606B58-10ED-4AC1-BDF5-43B579A56345.jpeg2.7 MB · Views: 47

31606B58-10ED-4AC1-BDF5-43B579A56345.jpeg2.7 MB · Views: 47 -

E798533B-D617-4A14-83E6-F95B722697A1.jpeg3.6 MB · Views: 47

E798533B-D617-4A14-83E6-F95B722697A1.jpeg3.6 MB · Views: 47 -

B6726A5A-BA92-4C23-9180-DEB5B5D2AA83.jpeg2.7 MB · Views: 48

B6726A5A-BA92-4C23-9180-DEB5B5D2AA83.jpeg2.7 MB · Views: 48 -

B6BD5642-E175-44C1-BFFC-23527CC17632.jpeg2.6 MB · Views: 45

B6BD5642-E175-44C1-BFFC-23527CC17632.jpeg2.6 MB · Views: 45 -

5ADD4C05-44F1-42D8-AA07-52A1C6FE7F8C.jpeg3.5 MB · Views: 45

5ADD4C05-44F1-42D8-AA07-52A1C6FE7F8C.jpeg3.5 MB · Views: 45 -

F2EE3D41-5F29-4490-839D-18AEB81E6792.jpeg3.5 MB · Views: 43

F2EE3D41-5F29-4490-839D-18AEB81E6792.jpeg3.5 MB · Views: 43 -

3C0244D5-F98E-4054-81C9-CBAC6AFE6AE9.jpeg1.6 MB · Views: 42

3C0244D5-F98E-4054-81C9-CBAC6AFE6AE9.jpeg1.6 MB · Views: 42 -

E3DC5271-89FD-4711-A17E-A8C03EE66AB1.jpeg2.1 MB · Views: 39

E3DC5271-89FD-4711-A17E-A8C03EE66AB1.jpeg2.1 MB · Views: 39 -

9BDA772A-EB54-4A80-ADD5-355BEBF124CA.jpeg3.5 MB · Views: 39

9BDA772A-EB54-4A80-ADD5-355BEBF124CA.jpeg3.5 MB · Views: 39 -

339D86A0-25F7-4554-BF1B-585E6B4F2420.jpeg1.8 MB · Views: 37

339D86A0-25F7-4554-BF1B-585E6B4F2420.jpeg1.8 MB · Views: 37 -

3573FC0F-8BFE-43D8-B23D-0CB555054252.jpeg1.8 MB · Views: 34

3573FC0F-8BFE-43D8-B23D-0CB555054252.jpeg1.8 MB · Views: 34 -

2A14CE30-C49D-48CE-BD3B-2AEBC4B8DCE3.jpeg2.1 MB · Views: 34

2A14CE30-C49D-48CE-BD3B-2AEBC4B8DCE3.jpeg2.1 MB · Views: 34 -

D2BF1A07-B780-4F58-A937-BB3A674C9B39.jpeg2.2 MB · Views: 45

D2BF1A07-B780-4F58-A937-BB3A674C9B39.jpeg2.2 MB · Views: 45