Slow forward progress...

New side panels are cut from some 1/2" ACX and awaiting a few coats of Spar.

Overcame my fear of drilling the through bolt holes in my new transom and just let her rip. Mocked everything up and she lines up perfectly! Now...do I over drill before epoxy and re-drill to correct size, or just leave it as is and liberally coat each bolt with some 5200 (which will be done regardless). Waiting for the temps to warm a bit before laying down the epoxy. Figure I'll need to re-drill anyhow unless I somehow plug the holes, so leaning toward the oversize option. How big do I go for a 1/4" final hole? Had a little tear out on the back side(inside) of the splashwell drain tube holes, but figure I'll smooth out whatever doesn't get filled with the epoxy with some MT or JB before covering with paint and installing the tubes. I have a set of the plastic tubes on hand, but debating ordering a set of the aluminum ones instead??

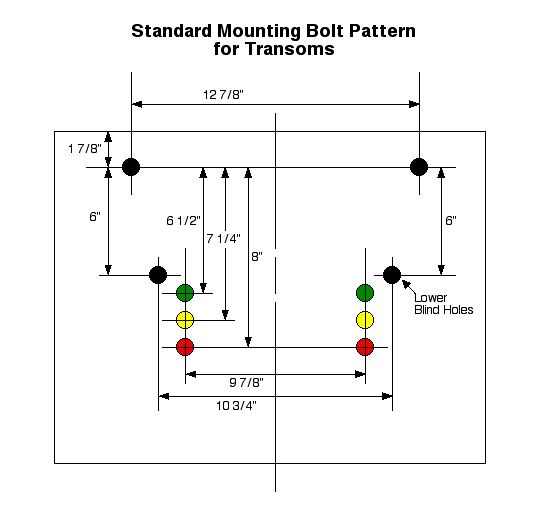

My other big fear was the motor mounting holes. Managed to wrestle one of the outboards off the stand to use as a template and transferred the mounting hole pattern to my aluminum transom pad. I'll install the transom pad with the pre-drilled 1/2" holes when I do the final installation of the transom. I'll then need to drill the through holes in the actual transom skin and transom, but everything should be all lined up accordingly with the transom pad as my template. My fabricated transom cap is made from a little larger c-channel than the original cap, so I had to account for where the transom pad will actually sit in relation to the top of the actual transom. I currently have my top motor mount holes set to be drilled 2" from the top of the actual transom. From what I can tell, this should be accurate, so please correct me if I'm down the wrong path and before I do the actual drilling. It's just holes in a transom pad at the moment. I do not plan to drill these until the transom is actually installed, so no over drilling and epoxy plugs. I think I'll just be asking for too much precision for the pad, skin, and transom to all line up perfectly.

Got a Five Oceans 6 gallon tank and fuel line on order, but unsure of what fittings to order. All the information I find for an '87 Mercury doesn't seem to line up with what I'm actually seeing at the motor. Can someone please point me in the right direction for the correct fuel line fitting for the included picture? 1987 Mercury Outboard.

I'll try to do better with my picture posting...my current work hasn't really been much to photograph :sleeping: