avpaulb

Petty Officer 1st Class

- Joined

- Jun 19, 2011

- Messages

- 298

Re: 1969 Larson - Big Project

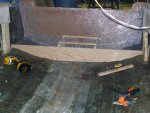

Looks like foam core ( little squares of foam 3/4"ish thick ) instead of balsa core on your hull sides.

For some reason I think that is probably Structural and should be replaced.

More pics and info needed though.

YD.[/QUOTE]

The only pics I have of it are those I've posted. HOWEVER, there is a guy doing a repair right now on the forum that has the EXACT same situation going on:

http://forums.iboats.com/showthread.php?t=544365&page=4

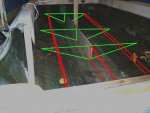

If you look at posts #56 and #78 he has a couple of good shots that show precisely what I had going on. The foam ran all the way up the hull sides, under the cap, from bow to stern. On top of the hull there was carpet glued in.

He isn't planning on doing a deck repair. When I removed my deck and started grinding up the sides of the hull to have a place to lay glass, that foam stuff just started coming right off. So, I removed it.

I figure I have two options...

A) Figure out a way to replace the foam. It wasn't squares, as you described, it was definitely blown in or somehow poured in.

B) If it was structural, could I not skip the foam idea and lay up some glass applications instead?

I'm good with either option. I think I've devised a way to do the foam in my head. It would be a ROYAL PITA, but I'm pretty sure my idea is solid.

I need to continue with the transom, stringers, deck anyway before I get to that point, so I have time to debate ideas!

Looks like foam core ( little squares of foam 3/4"ish thick ) instead of balsa core on your hull sides.

For some reason I think that is probably Structural and should be replaced.

More pics and info needed though.

YD.[/QUOTE]

The only pics I have of it are those I've posted. HOWEVER, there is a guy doing a repair right now on the forum that has the EXACT same situation going on:

http://forums.iboats.com/showthread.php?t=544365&page=4

If you look at posts #56 and #78 he has a couple of good shots that show precisely what I had going on. The foam ran all the way up the hull sides, under the cap, from bow to stern. On top of the hull there was carpet glued in.

He isn't planning on doing a deck repair. When I removed my deck and started grinding up the sides of the hull to have a place to lay glass, that foam stuff just started coming right off. So, I removed it.

I figure I have two options...

A) Figure out a way to replace the foam. It wasn't squares, as you described, it was definitely blown in or somehow poured in.

B) If it was structural, could I not skip the foam idea and lay up some glass applications instead?

I'm good with either option. I think I've devised a way to do the foam in my head. It would be a ROYAL PITA, but I'm pretty sure my idea is solid.

I need to continue with the transom, stringers, deck anyway before I get to that point, so I have time to debate ideas!