j_k_bisson

Lieutenant Junior Grade

- Joined

- Oct 6, 2010

- Messages

- 1,082

Re: Update 01-28-2011 cont'd Rev-2

Re: Update 01-28-2011 cont'd Rev-2

I was just looking at this site myself. I also just got off the phone with the people that I order the gasket set from. Had to switch over to the big bore 88-92 full set.

So when I get it brought in for honing, if it is out of spec I can still have it bored to the next size up. At least there is options here.....

Question one; I have a full set of ignition for a 200-225 1987, can this be used on a 1988 225hp.

Second one; what carbs am I supposed to be running?

Third; How do I tell what model power ead I have?

Thanks for all the help. This is going to be one of those frankenstien/junk yard motors, I pretty sure of it now. This is going to be fun!!!!

Re: Update 01-28-2011 cont'd Rev-2

Jeff the bore size you posted clearly places you out of the 86/87 Year , this is the big bore 88 or up which your bore size matches .

As for oversize options .40 is max if not a re-sleeve which is expensive way to go period.

Please go the this site and plug in your information you will see why I am concern..If you install the wrong size jets/carbs you will be in doing this all over again.

http://www.wiseco.com/ProductSearch.aspx

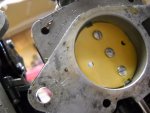

Bore - Standard: 3.685in

Bore - Actual: 3.715in

Bore - Oversize: .030in

Cylinder Position: Starboard

Note: Loop Charge

I was just looking at this site myself. I also just got off the phone with the people that I order the gasket set from. Had to switch over to the big bore 88-92 full set.

So when I get it brought in for honing, if it is out of spec I can still have it bored to the next size up. At least there is options here.....

Question one; I have a full set of ignition for a 200-225 1987, can this be used on a 1988 225hp.

Second one; what carbs am I supposed to be running?

Third; How do I tell what model power ead I have?

Thanks for all the help. This is going to be one of those frankenstien/junk yard motors, I pretty sure of it now. This is going to be fun!!!!