maryhannaj

Chief Petty Officer

- Joined

- Sep 22, 2013

- Messages

- 422

Re: 1982 Glastron Hpv165 bass boat restoration.

Hey banshee owner. Thanks for the link to the calculator. Unfortunately I dont have any apple compatible devices. I can view what it is, but I can't download it. I'll have to follow behind you on that and see if my devices app store has something that will do the same thing. Thanks for the idea. I also thought to just use a fabric tape measure to measure all of the angles of the inside of the hull and try to do the math from there.

Today I ground on that hull for another 5 or 6 hours. Man, this is a slow moving process for sure. I'll just say that I still have quite a lot left to do. I'm gettin there though, peice by peice. There is just do much build up of resin and fiberglass around where the stringers, flotation pods, transom and where they filled and leveled off the huge gaps that were left in between the floor panels and the hull. I'll be so dang happy when the grinding is finished so I can start building my transom and stringers.

I do feel like I'm beginning to make a bit of progress with it but it's just gonna take a lot of time I think. I can't even imagine how trashed and dusty the garage would be without the shelter.

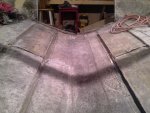

In this photo it shows the grind area. It's pretty similiar to this all of the way around the hull where the gaps between the sole and the hull were filled in. It's also like this along where every other peice of structure was tabbed into the hull.

Instead of grinding it down to the hull last time the work was done, they just ground over the other glass, filled in as many gaps as they could with this greenish colored fiberglass filler, and then re glassed right back over the top of it. There are huge air voids, cracks, gaps and areas of unsoaked glass that will just kind of fall off.

I can't imagine this is the way it should have been done.

Hey banshee owner. Thanks for the link to the calculator. Unfortunately I dont have any apple compatible devices. I can view what it is, but I can't download it. I'll have to follow behind you on that and see if my devices app store has something that will do the same thing. Thanks for the idea. I also thought to just use a fabric tape measure to measure all of the angles of the inside of the hull and try to do the math from there.

Today I ground on that hull for another 5 or 6 hours. Man, this is a slow moving process for sure. I'll just say that I still have quite a lot left to do. I'm gettin there though, peice by peice. There is just do much build up of resin and fiberglass around where the stringers, flotation pods, transom and where they filled and leveled off the huge gaps that were left in between the floor panels and the hull. I'll be so dang happy when the grinding is finished so I can start building my transom and stringers.

I do feel like I'm beginning to make a bit of progress with it but it's just gonna take a lot of time I think. I can't even imagine how trashed and dusty the garage would be without the shelter.

In this photo it shows the grind area. It's pretty similiar to this all of the way around the hull where the gaps between the sole and the hull were filled in. It's also like this along where every other peice of structure was tabbed into the hull.

Instead of grinding it down to the hull last time the work was done, they just ground over the other glass, filled in as many gaps as they could with this greenish colored fiberglass filler, and then re glassed right back over the top of it. There are huge air voids, cracks, gaps and areas of unsoaked glass that will just kind of fall off.

I can't imagine this is the way it should have been done.