Re: Transom problems with Larson 186 SEI I/O Bowrider

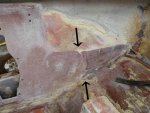

I took advantage of some warm weather this weekend and finished the glassing of the transom core. Per Woodonglass's transom how-to instructions, I added fillets around the edges of the transom and tabbed it in with CSM. Since the tabbing on the bottom of the transom goes right up to the keyhole, I added a later of CSM around the perimeter of the keyhole to keep the thickness of transom perfectly even from top to bottom.

Next, I skinned the entire transom with two layers of 1708.

Because of the contours in the hull on the back of the boat, other than at the very top of the transom, there is no place to tab the upper angled edges of the transom to the hull. I guess I won't worry about it, as I've already got more fiberglass on this than it had coming from the factory.

I have a couple of small bubbles (about the size of a nickel) in the glass along the bottom of the transom, over the fillet. I'm not too worried about them causing the glass to be weak, but I am concerned about them being a place where water could infiltrate and get trapped. I plan to use a hypodermic needle to inject resin into the bubble. If that doesn't work, I guess I'll grind those areas down and re-glass.

One thing that worked really well: I used Yacht Dr.'s tip of brushing over fillets (before they cured) with a resin-soaked brush to eliminate little snags. As a result, I had to do almost no grinding/sanding to smooth out the peanut butter.

Next on my agenda (after I clean up the keyhole) is glass back in the engineered stringers where I cut them out to fit in the transom. Then I'll clean up the hull where the deck was attached and get ready to fit the new deck pieces. I want to be ready for warm weather so I can install the deck and two-part foam, and glass everything in. Feels good to be moving along!

Jim