Re: Starcraft Holiday Reno and Hull Repair

Well, it's been a year since I first posted, so I'll add some progress reports. I got her back in the water a few times this past summer (sorry, no splash pics). We never had more than a tablespoon of bilge water when I pulled the plug out as is my habit when we trailer. That tablespoon may have been from spray while I entertained the grandkids and exercised the hull repair on the biggest waves I could find.

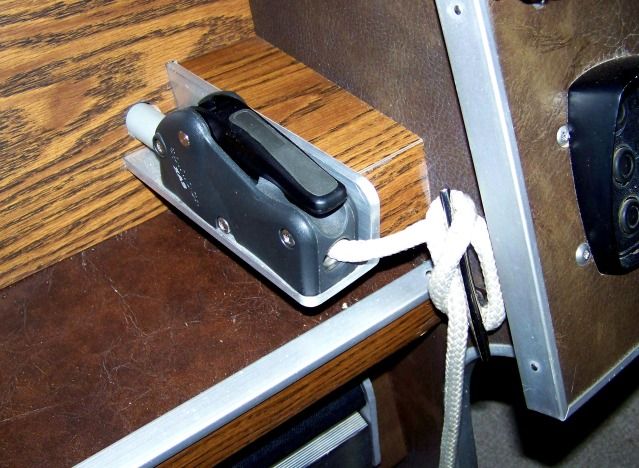

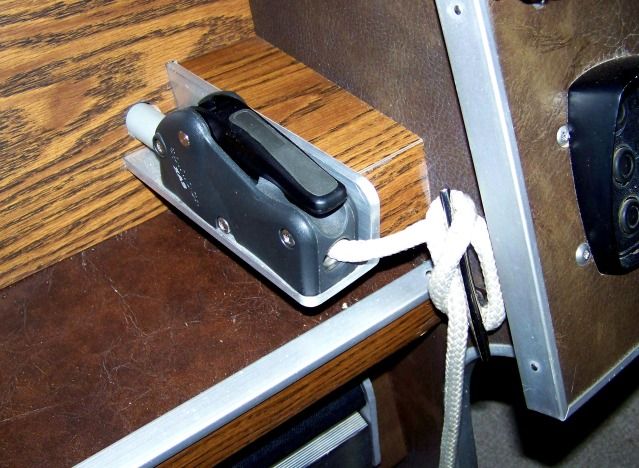

I decided I didn't like the location of the anchor line safety cleat on the helm side of the console and relocated it where it's more convenient, right beside the rope clutch. It's good to avoid clutter, but some things are probably better where you can keep an eye on them. I had some difficulty anchoring as the shockle passed through the bale on the bow roller. I made a larger SS bale, but it was still troublesome, so I removed the shockle altogether. Surprisingly, the delta anchor doesn't rattle or bounce at all in the roller, which was my sole purpose for using the shockle.

When I decided to install a bow roller, I knew I had to replace the combination red/green bow light and settled on locating individual red and green lights on either side of the roller. I planned to use a Bruce claw anchor type, but changed my mind after a salesman convinced me that a Delta would self-launch better. OOPS. I had the lights mounted and wired when I realized that the Delta has a higher profile than the Bruce and the flukes would obscure the lights when viewed from straight ahead. So they had to move again.

I still had scraps of the composite decking available, so my best option was to replace the holed pieces of decking. I found that the material was actually very easy to cut with my oscillating saw and then chisel out in prep for new material.

I don't like the additional butt seams, but overall, the repair is not that noticeable.

I relocated the lights (their 4th location) to a point on either side of the windshield. They are compact and low profile, but visible throughout their required range. - Grandad