- Joined

- Jul 18, 2011

- Messages

- 18,085

It looks like our next boat is still a few years away, so I am thinking about doing some enhancements to the current barge, a Formula 330 Sun Sport. I always wanted an extended swim platform to get the people out beyond the outdrives, as they present a mild hazard when doing the sandbar thing.

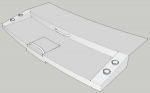

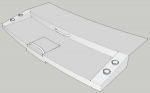

Formula has some nice extended swim platforms as an option on their new boats, like the one pictured below. Knowing Formula's prices, I'm sure something like this through them would be more than most boats cost.

So, I'm thinking of a DIY approach . . .

I would like to make something myself similar to it, using the 'plug & mold' technique so I can make a true fiberglass (no wood) platform that looks factory.

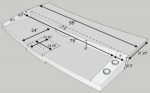

I have a design sketched out that is similar to the Formula option, as shown below:

My plan is to move the existing boarding ladder to the extended platform and install a second grab rail on the riser up to the built-in platform. This should get the ladder about 1 to 1.5 feet beyond the outdrives in their tilted up fashion.

I would make the 'plug' out of EPS foam, then epoxy coat it and finish it to a shine. Then make a mold from the plug using fiberglass and some stiffeners to hold the mold true (probably those stiffeners can be plywood). Then I would prep the mold for fiberglass and do vacuum bagged mold to get a high strength-to-weight ratio. I probably will form some stiffeners underneath with some urethane foam pieces and then have some stainless steel support rods running down to the transom, as most installations have.

I am thinking the whole thing could be done for about $1200 in materials. I'll probably take some measurements this weekend and maybe buy the EPS sheets.

At this stage I am looking for any input, comments, ideas, etc. :noidea:

I have seen the after market platforms that you can get for around $3K. Not that excited about those, as I like the lower level of the 'step-down' style of platform, since the regular platform of my boat is fairly high up from the waterline.

Formula has some nice extended swim platforms as an option on their new boats, like the one pictured below. Knowing Formula's prices, I'm sure something like this through them would be more than most boats cost.

So, I'm thinking of a DIY approach . . .

I would like to make something myself similar to it, using the 'plug & mold' technique so I can make a true fiberglass (no wood) platform that looks factory.

I have a design sketched out that is similar to the Formula option, as shown below:

My plan is to move the existing boarding ladder to the extended platform and install a second grab rail on the riser up to the built-in platform. This should get the ladder about 1 to 1.5 feet beyond the outdrives in their tilted up fashion.

I would make the 'plug' out of EPS foam, then epoxy coat it and finish it to a shine. Then make a mold from the plug using fiberglass and some stiffeners to hold the mold true (probably those stiffeners can be plywood). Then I would prep the mold for fiberglass and do vacuum bagged mold to get a high strength-to-weight ratio. I probably will form some stiffeners underneath with some urethane foam pieces and then have some stainless steel support rods running down to the transom, as most installations have.

I am thinking the whole thing could be done for about $1200 in materials. I'll probably take some measurements this weekend and maybe buy the EPS sheets.

At this stage I am looking for any input, comments, ideas, etc. :noidea:

I have seen the after market platforms that you can get for around $3K. Not that excited about those, as I like the lower level of the 'step-down' style of platform, since the regular platform of my boat is fairly high up from the waterline.