GCartwright

Petty Officer 2nd Class

- Joined

- Jul 1, 2012

- Messages

- 149

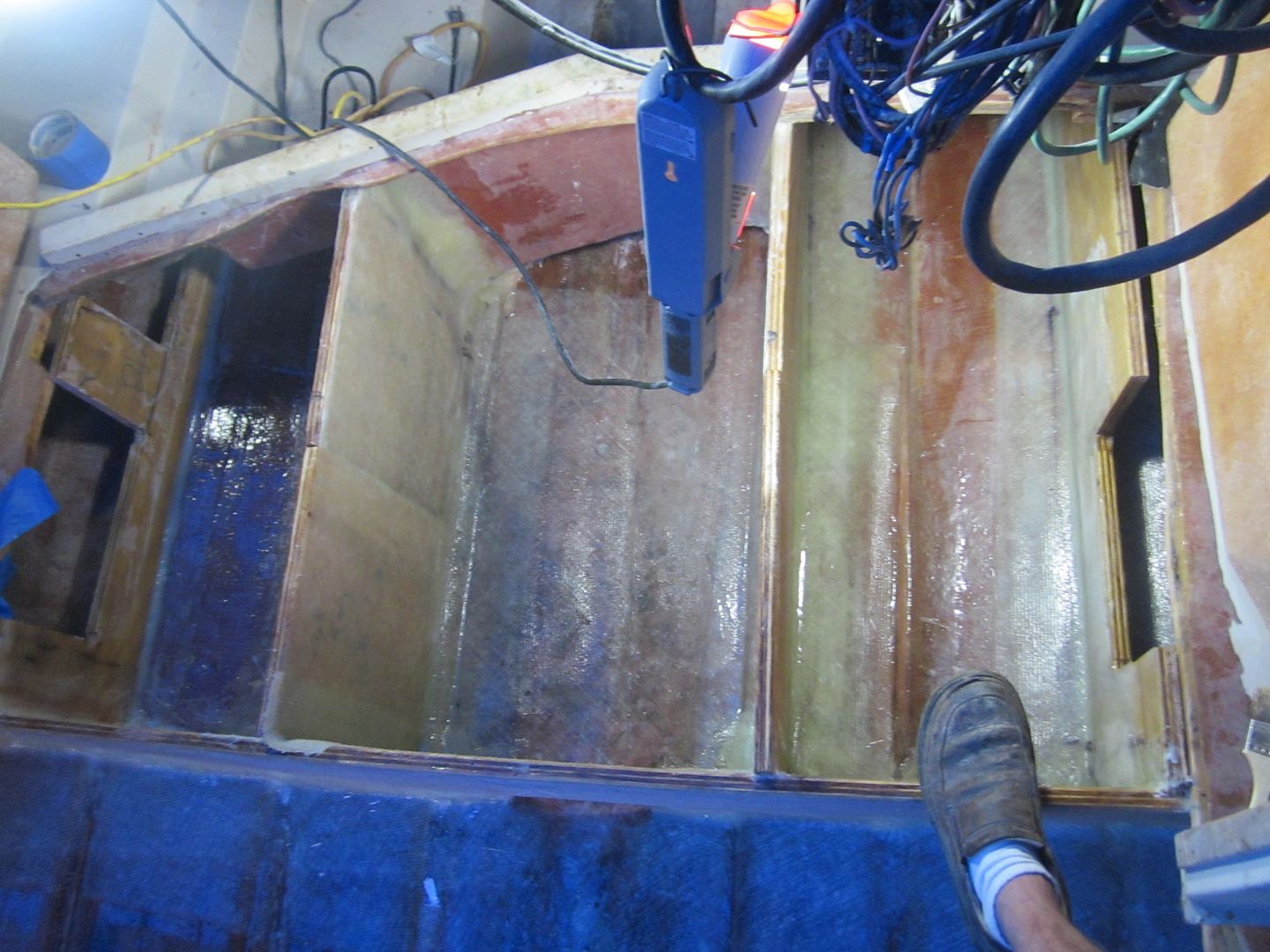

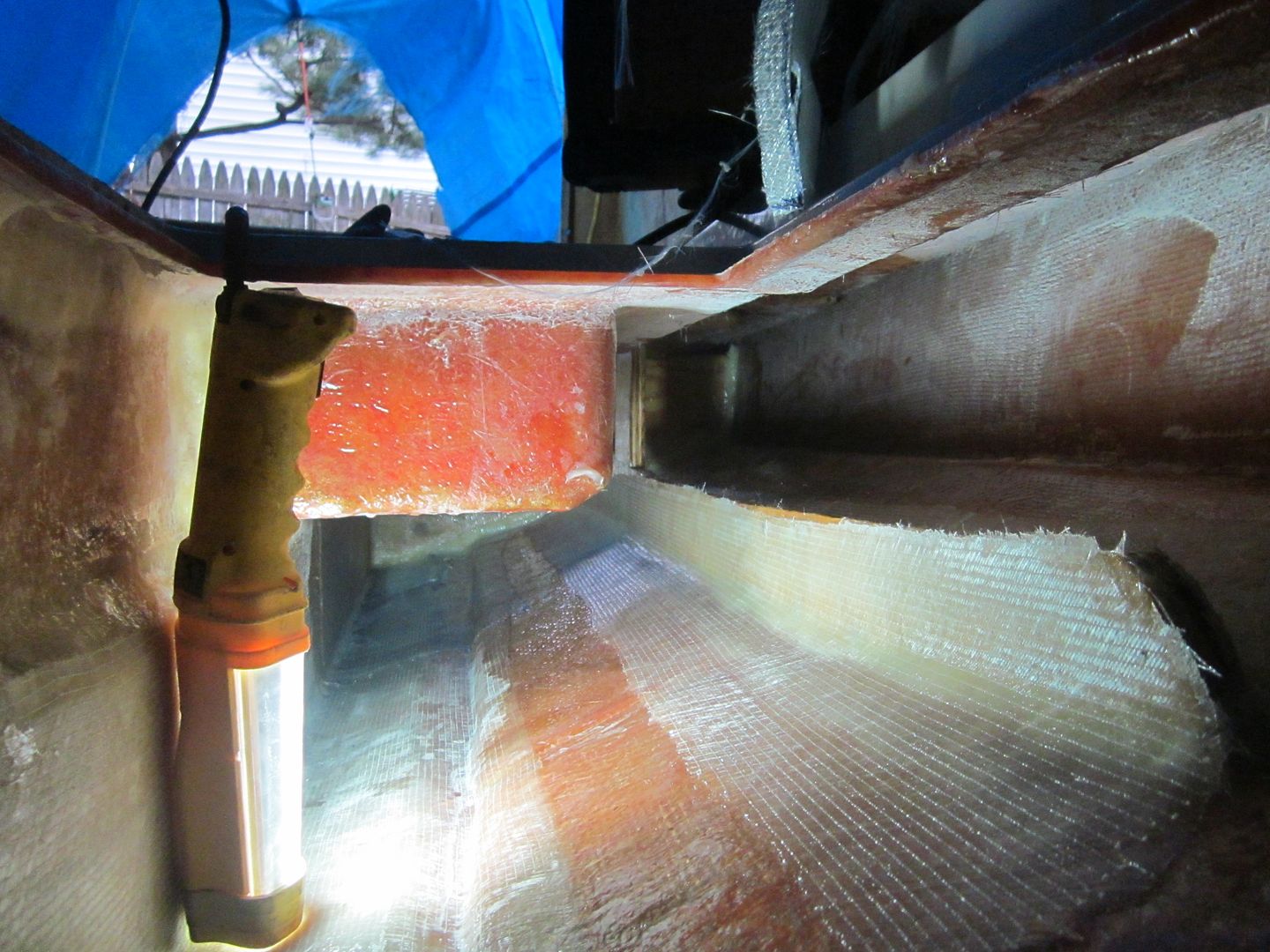

I'm looking for some guidance on evaluating the condition of the transom and stringers. I have removed the engine for a steering swivel pin seal leak and now have good access to the transom for inspection.

The keyhole area seems dry and solid. When I drilled exploratory holes into the lower transom water was dripping out of the drilled holes. The lower thinner section of the transom is about 3/8" thick, about 3/16" of gel coat and 3/16" of plywood and inner skin. Water was able to get access around the garbord drain not being sealed properly. The few holes I have drilled in the thicker area of the transom appears to be dry wood.

I can see rot in one of the stringers where an engine bay access cover was screwed into a cleat, water got into the cleat and rot spread to the stringer, will get pictures posted of this shortly.

Would appreciate opinions on what I may be dealing with and recommendations on more tests etc

The keyhole area seems dry and solid. When I drilled exploratory holes into the lower transom water was dripping out of the drilled holes. The lower thinner section of the transom is about 3/8" thick, about 3/16" of gel coat and 3/16" of plywood and inner skin. Water was able to get access around the garbord drain not being sealed properly. The few holes I have drilled in the thicker area of the transom appears to be dry wood.

I can see rot in one of the stringers where an engine bay access cover was screwed into a cleat, water got into the cleat and rot spread to the stringer, will get pictures posted of this shortly.

Would appreciate opinions on what I may be dealing with and recommendations on more tests etc