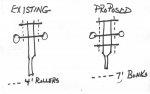

I am getting ready to rework and older trailer. It was constructed in the old style with twin center beams about a foot apart and the rollers in the rear were supported with a piece of steel channel bolted perpendicular to the main runners ( think T shaped). This was done using 3/16" 4 x 2 steel channel. The 2" portion carries the load. It must have been custom work cause you can't buy that now. 44" total span from port to starboard.

My I hope simple questions are:

If the smaller, 2" dimension is carrying the vertical load does the width of the channel influence the carrying capacity at all? Would not a 3 x 2 be just as strong as a 4 x 2?

Two inch is not available; 1.72" and 1.5" are. How much would you down grade the capacity for each of those two sizes?

A second cross piece is being added for a total of 3 (the axle is one) so the total load on each will be less than it was before. Also the boat is just a 14' tinny at about 350 pounds max with motor though I would like some cushion for a motor upgrade in the future.

My I hope simple questions are:

If the smaller, 2" dimension is carrying the vertical load does the width of the channel influence the carrying capacity at all? Would not a 3 x 2 be just as strong as a 4 x 2?

Two inch is not available; 1.72" and 1.5" are. How much would you down grade the capacity for each of those two sizes?

A second cross piece is being added for a total of 3 (the axle is one) so the total load on each will be less than it was before. Also the boat is just a 14' tinny at about 350 pounds max with motor though I would like some cushion for a motor upgrade in the future.