ESGWheel

Ensign

- Joined

- Aug 29, 2015

- Messages

- 903

This post is intended to be a complete collection of information regarding ‘fuel pump whine’, an issue plaguing many of the older VP MPI engines. If there is info or processes missed, please add them in to help make this complete for others struggling with this issue. While this post focuses on the 5.0 and 5.7 regarding the parts it should have applicability beyond those two for the info and process. Hopefully it will be helpful for those trying to get this issue permanently resolved.

Symptoms: a high-pitched whine noise from the pump, either intermittent or continuous. Hot to the touch high pressure pump and electrical connector. Pressure more than 60 PSI on the fuel rail (spec is 58). Can also have rough running, stumbling and/or limited high rpms due to fuel starvation. In one extreme case, I read a comment on Man Cave Mechanic’s You Tube video that attributed his ruined 8.1 motor to cylinders 1, 3 and 6 leaning out due to paint debris clogging the injectors.

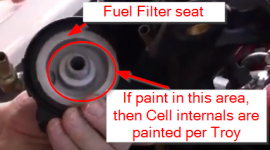

Cause: these pumps have internal paint that deteriorates overtime (due to ethanol fuel) and flakes off plugging up pump passages, the pressure regulator, and injectors. This in turn creates a higher backpressure and lower flow causing it to whine and draw more current and/or fuel starvation to the high-pressure pump also causing a whine.

Solution: Need to (1) replace or repair the pump (removing the internal paint) AND (2) clean out the rest of the fuel system. Both are required but can potentially do a ‘quick fix’ to keep on the water until a full permanent fix is done. Example: simply cleaning the screen on the pressure regulator may keep you going until can do more. Troy’s (Man Cave Mechanic) videos provide an excellent ‘how to check for paint debris’ and do an initial cleaning. Link is below.

For the Pump > several options exist:

Option A) quickest ‘back on the water’ solution is an Aftermarket (AM) pump that can be bought these days for less than $200. Note: I am unsure if the AM pumps have internal paint, so may not be a long-term solution.

Option B) send pump to Troy for internal paint removal and rebuilding.

Option C) get an AM pump to keep going on the water and send in your VP pump to Troy for paint removal and rebuilding. Once back in hand, put back in and save the AM pump as a backup (what I did).

Option D) clean and rebuild the VP yourself.

For Cleaning > several steps for this:

1) Pull out the fuel pressure regulator and clean off its screen. Ideally and if applicable, remove the screen and replace with the E clip as per VP Bulletin P-23-7. There is a Bosch branded regulator is available for abt $20 that is a direct replacement and has the same pressure output.

2) Pull off the fuel rail and thoroughly clean it out. Carb Cleaner works. Use low pressure compressed air to clean and blow out the fuel hoses. Be cautious of using canned cleaners to preclude softening the hose or O-Rings. Or simply replace the lines if they are aged more than 15 years as a preventive maintenance item.

3) Pull out the injectors and have them serviced. A ‘keep on the water’ solution is to buy a set of AM injectors and install those while sending off the VP ones for cleaning. All 8 AM injectors can be had for about $50. Alternatively have your OEM injectors cleaned during the off season. Doing (2) and (3) together is best.

+++===+++

Links and/or Part Nos. Note I have personally used all the below with success on my 2005 5.0 GXi-E.

Symptoms: a high-pitched whine noise from the pump, either intermittent or continuous. Hot to the touch high pressure pump and electrical connector. Pressure more than 60 PSI on the fuel rail (spec is 58). Can also have rough running, stumbling and/or limited high rpms due to fuel starvation. In one extreme case, I read a comment on Man Cave Mechanic’s You Tube video that attributed his ruined 8.1 motor to cylinders 1, 3 and 6 leaning out due to paint debris clogging the injectors.

Cause: these pumps have internal paint that deteriorates overtime (due to ethanol fuel) and flakes off plugging up pump passages, the pressure regulator, and injectors. This in turn creates a higher backpressure and lower flow causing it to whine and draw more current and/or fuel starvation to the high-pressure pump also causing a whine.

Solution: Need to (1) replace or repair the pump (removing the internal paint) AND (2) clean out the rest of the fuel system. Both are required but can potentially do a ‘quick fix’ to keep on the water until a full permanent fix is done. Example: simply cleaning the screen on the pressure regulator may keep you going until can do more. Troy’s (Man Cave Mechanic) videos provide an excellent ‘how to check for paint debris’ and do an initial cleaning. Link is below.

For the Pump > several options exist:

Option A) quickest ‘back on the water’ solution is an Aftermarket (AM) pump that can be bought these days for less than $200. Note: I am unsure if the AM pumps have internal paint, so may not be a long-term solution.

Option B) send pump to Troy for internal paint removal and rebuilding.

Option C) get an AM pump to keep going on the water and send in your VP pump to Troy for paint removal and rebuilding. Once back in hand, put back in and save the AM pump as a backup (what I did).

Option D) clean and rebuild the VP yourself.

For Cleaning > several steps for this:

1) Pull out the fuel pressure regulator and clean off its screen. Ideally and if applicable, remove the screen and replace with the E clip as per VP Bulletin P-23-7. There is a Bosch branded regulator is available for abt $20 that is a direct replacement and has the same pressure output.

2) Pull off the fuel rail and thoroughly clean it out. Carb Cleaner works. Use low pressure compressed air to clean and blow out the fuel hoses. Be cautious of using canned cleaners to preclude softening the hose or O-Rings. Or simply replace the lines if they are aged more than 15 years as a preventive maintenance item.

3) Pull out the injectors and have them serviced. A ‘keep on the water’ solution is to buy a set of AM injectors and install those while sending off the VP ones for cleaning. All 8 AM injectors can be had for about $50. Alternatively have your OEM injectors cleaned during the off season. Doing (2) and (3) together is best.

+++===+++

Links and/or Part Nos. Note I have personally used all the below with success on my 2005 5.0 GXi-E.

- AM Fuel Pump: Link

- Cave Man Mechanic pump service and excellent how to videos: Link and link

- E Clip Bulletin Group P-23-7 No.3 Version 01: link and also on Man Cave Mechanic website

- E Clip part: available from Man Cave Mechanic and other resources.

- BOSCH Fuel Pressure Regulator Part No. 0280160575 link

- AM Injectors: search eBay and other sites (seller I bought from no longer has new, only reman).

- Fuel Injector Cleaning Services: many and varied. Look for one that will provide written report as well as runs the range of speeds. The one I used also provided the injector O-Rings savings a bundle on buying those. I used Marren located in CT link

- Tools: Fuel Pressure Tester OTC 5630 link and Fuel Line Disconnect Tool Set ARES 70317 link. Many others exist.

- My previous posting about Fuel Pump Whine and E Clip installation with pictures: link