CaptnO,

Assuming pulley is not loose on the shaft, runout is caused by either a bent pulley or a bent shaft or both. Thus, fixing can be replacing the pulley only or the entire pump assembly.

However, I re-read the entire post and three things stood out to me.

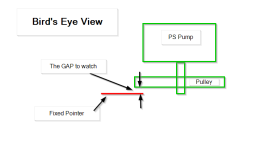

- In post 8 Lou commented that in the video the below appears to be rubbing against the tensioner. And looking at it, it sure does.

- And in post 11 you stated that it is not rubbing as much with the new belt. The belt should NEVER be rubbing against anything.

- The 3rd thing is I could not find your year and model of your engine.

I know this has been very frustrating and here is my heartfelt suggestion:

Post your engine year and model > with this find the correct serpentine belt threading diagram and belt part no. Someone on this forum will have both if you cannot find it.

Carefully compare the diagram with your set up. Look for not only the route of the but also the relative locations of the pulleys and tensioner. Google your engine as well and look for an actual picture someone has taken of their motor and use that as another reference. If anything looks off, post those results with pictures, etc.

Get yourself a VP belt of the proper part number and install per the diagram. Do not depend on a cross reference chart for an alternative. Get a VP branded one. Check for that clearance of the tensioner. And post results.

In brief, go back to basics. I suspect you could thread on a belt in your sleep so who am I to suggested it may be threaded wrong? I mean no offence. But it’s like proofreading your own writing. You know what you wrote and never pick up on the ‘and

and’ in your sentence but when you read every word out loud you pick up on it. I am suggesting something akin: you know the path by heart but when you diligently compare it to the OEM diagram you have an ah ha moment.

Once all that is done and verified and nothing is different, we continue on the what the heck is going on. I can confidently say this: belts should not wear like you are experiencing and it can be fixed.