In 2015 I had a supposed professional replace the stringers and floor in a 1969 run-about. the original picture is what they removed from the boat. Image repair1 and repair2 were taken as they did the work. Jump forward to a few weeks ago, and it seems the cover was collecting water on the starboard rear corner for the past 2 years. The boat was raised in the front and based on how the floor and stringers have softened, the water was enough to fill the outer stringer, then overflow to the second stringer.

the outer stringer is all but paper, the back 6' of the second stringer is lost..

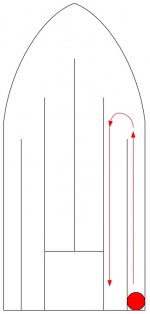

I've read a lot of the posts on the forum, but haven't seen my question of placing weep holes at strategic locations on the stringers.

Judging from these pictures, the company did not put any horizontal support between the stringers. (The foam is quite stiff.)

the plywood stringers are not wrapped 100% in fiberglass.

I will be replacing the entire outer starboard stringer and about 7' of the adjacent stringer.

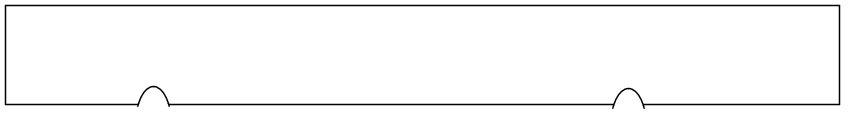

I plan to use cedar, I plan to put 1/2 moon weep holes at the rear and middle of the stringers.

I plan to wrap the stringer in fiberglass.

I plan to add weep holes into the engine box.

I also plan to glue a sheet of aluminum onto the rear starboard area of the floor that curls up the walls, and transom, and lips over into the engine box area, then glue down the replacement carpet.

All comments are greatly appreciated.

andrewt57

the outer stringer is all but paper, the back 6' of the second stringer is lost..

I've read a lot of the posts on the forum, but haven't seen my question of placing weep holes at strategic locations on the stringers.

Judging from these pictures, the company did not put any horizontal support between the stringers. (The foam is quite stiff.)

the plywood stringers are not wrapped 100% in fiberglass.

I will be replacing the entire outer starboard stringer and about 7' of the adjacent stringer.

I plan to use cedar, I plan to put 1/2 moon weep holes at the rear and middle of the stringers.

I plan to wrap the stringer in fiberglass.

I plan to add weep holes into the engine box.

I also plan to glue a sheet of aluminum onto the rear starboard area of the floor that curls up the walls, and transom, and lips over into the engine box area, then glue down the replacement carpet.

All comments are greatly appreciated.

andrewt57