De strong head

Recruit

- Joined

- Mar 20, 2024

- Messages

- 5

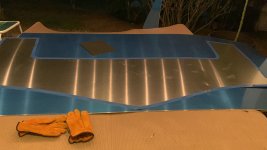

Hello everybody, I’m new in the forum, Im from Mexico ( so sorry if my typing has some mistakes). I have a MR 220 that have been resorting for the last months, was my dreamed boat, so didn’t hesitate with the deal, everything was nice looking and aparently in good shape . Once that I start assessing meticulously found obviously rotten transom and too many shi@“$ repairs(like putting a fiberglass skin all over the bottom of the hull) that cause a lot of corrosion by electrolysis… of course, is a 1988 model so what can I spect? Since few years ago, I had the idea of rebuild my dream boat, and here we go…