I have a Selectrim installed on my 1985 Beachcraft Cuddy with 5.7L (305ci) and right now it does not work as the previous owners cut the electrical wires and just left the hydraulic parts installed.

This trim system was designed decades ago and I wonder just how many boat owners out there that have this trim system have it still hooked up and operational? Does this trim system make that much difference in the water? Has it worked out that well over the years, that owners kept the system operational?

I think all I have to do is hook the wiring back up and get it operational. The parts look OK. The hydraulic lines are good.

So is it worth the time to get it back fully operational?

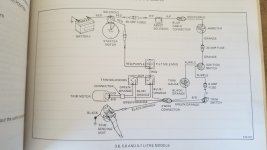

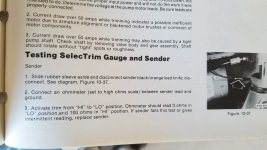

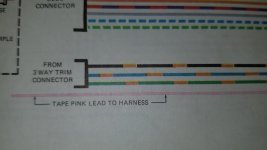

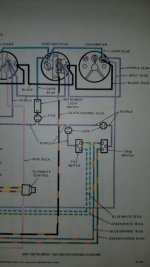

The OMC Stern Drive service manual (part no 506580 K-79) has very little on this. Maybe a newer manual has more info, especially the wiring diagram?

Any help from those who have this system is appreciated.

This trim system was designed decades ago and I wonder just how many boat owners out there that have this trim system have it still hooked up and operational? Does this trim system make that much difference in the water? Has it worked out that well over the years, that owners kept the system operational?

I think all I have to do is hook the wiring back up and get it operational. The parts look OK. The hydraulic lines are good.

So is it worth the time to get it back fully operational?

The OMC Stern Drive service manual (part no 506580 K-79) has very little on this. Maybe a newer manual has more info, especially the wiring diagram?

Any help from those who have this system is appreciated.