DrunkenSailor2020

Recruit

- Joined

- Oct 29, 2020

- Messages

- 4

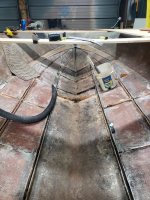

Lets start at the beginning. the boat was purchased in 95 by my father when i was 9. it's been in the family ever since. it's had a myriad of hot small block motors over the years, had the outdrive upgraded to a bravo 1, drive shower, been gel coated about 20 years ago, interior about 15 years ago. was running a stock motor for last 13 years or so. It hasn't had much love ever since and was run hard and put away wet. Went to upgrade the tired motor about 2 years ago and found rotten motor mounts. Had them replaced. went to install motor and discovered rotten transom. upon further digging, nearly every piece of wood in the stringer system and the plywood in the cabin floor was rotten as well. started doing some research (see link)

https://forums.iboats.com/threads/1985-21-wellcraft.576503/

decided to take another route and broke the boat down into its main three sections, the top, the engine bay, and the lower hull. the top has the cockpit floor attached to it, it's all one molded piece.

SEE ATTACHED PICTURES, TO BE CONTINUED IN NEXT POST.

https://forums.iboats.com/threads/1985-21-wellcraft.576503/

decided to take another route and broke the boat down into its main three sections, the top, the engine bay, and the lower hull. the top has the cockpit floor attached to it, it's all one molded piece.

SEE ATTACHED PICTURES, TO BE CONTINUED IN NEXT POST.

Attachments

-

IMG_20180610_150902425.jpg5.2 MB · Views: 16

IMG_20180610_150902425.jpg5.2 MB · Views: 16 -

IMG_20180610_150930256.jpg4.4 MB · Views: 15

IMG_20180610_150930256.jpg4.4 MB · Views: 15 -

IMG_20180610_150938689.jpg3.9 MB · Views: 14

IMG_20180610_150938689.jpg3.9 MB · Views: 14 -

IMG_20180615_101957986.jpg5.9 MB · Views: 14

IMG_20180615_101957986.jpg5.9 MB · Views: 14 -

IMG_20180615_102035484.jpg5 MB · Views: 14

IMG_20180615_102035484.jpg5 MB · Views: 14 -

20181125_163107.jpg4.6 MB · Views: 16

20181125_163107.jpg4.6 MB · Views: 16 -

20190923_205242.jpg3.3 MB · Views: 16

20190923_205242.jpg3.3 MB · Views: 16 -

20190928_114455.jpg3.4 MB · Views: 14

20190928_114455.jpg3.4 MB · Views: 14 -

20190928_114521.jpg4.5 MB · Views: 13

20190928_114521.jpg4.5 MB · Views: 13 -

20190928_114527.jpg3.7 MB · Views: 12

20190928_114527.jpg3.7 MB · Views: 12 -

20190928_123126.jpg3.9 MB · Views: 11

20190928_123126.jpg3.9 MB · Views: 11 -

20191002_223507.jpg1.9 MB · Views: 11

20191002_223507.jpg1.9 MB · Views: 11 -

20191002_223530.jpg3.8 MB · Views: 13

20191002_223530.jpg3.8 MB · Views: 13 -

20191002_223546.jpg4 MB · Views: 13

20191002_223546.jpg4 MB · Views: 13 -

20191006_142322.jpg2.1 MB · Views: 11

20191006_142322.jpg2.1 MB · Views: 11 -

20191006_142401.jpg3.9 MB · Views: 13

20191006_142401.jpg3.9 MB · Views: 13 -

20191006_150058.jpg2.3 MB · Views: 15

20191006_150058.jpg2.3 MB · Views: 15 -

20191006_150142.jpg5.1 MB · Views: 16

20191006_150142.jpg5.1 MB · Views: 16