jrttoday

Lieutenant Junior Grade

- Joined

- Feb 8, 2010

- Messages

- 1,081

that's typical and of my signature line, which can be read different ways -

don't presume I'm thinking or

don't let your thinking interrupt my thinking or

I don't think that I'm thinking!!!

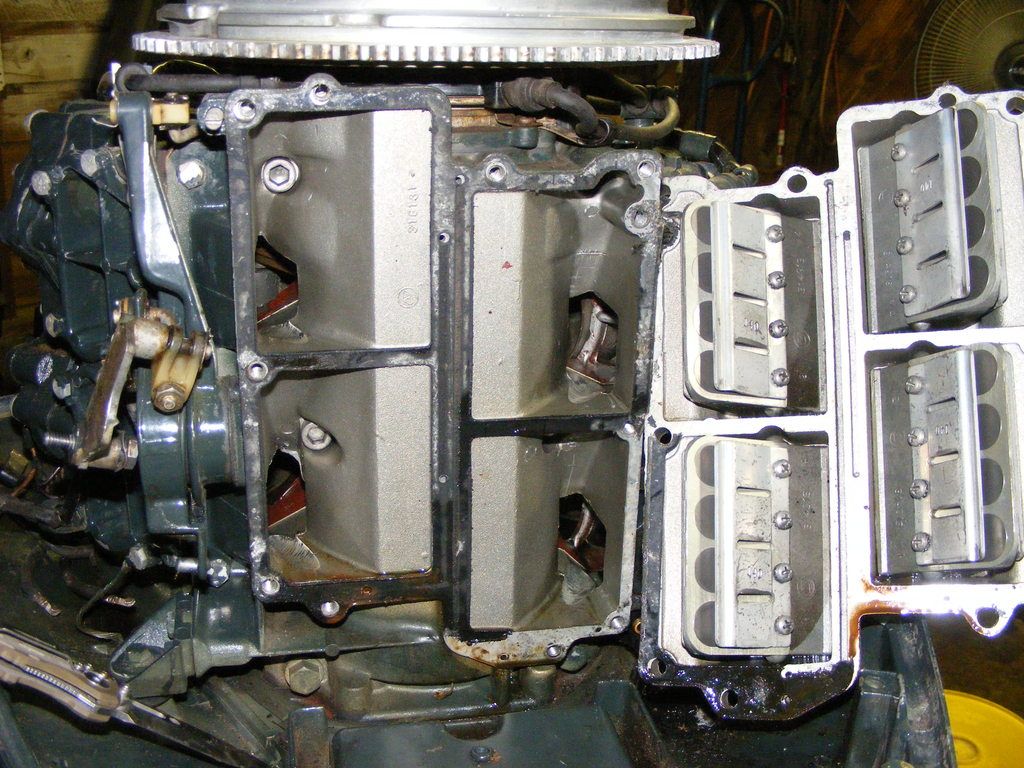

The only reason I posted the first pic and explained about it is that I used the flat bar to make the plugs. I think I need some rest lol

don't presume I'm thinking or

don't let your thinking interrupt my thinking or

I don't think that I'm thinking!!!

The only reason I posted the first pic and explained about it is that I used the flat bar to make the plugs. I think I need some rest lol