homelite

Petty Officer 2nd Class

- Joined

- Aug 13, 2002

- Messages

- 160

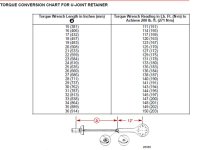

Hello. I pulled my driveshaft out and replaced the pinion seal and yoke. In reading my Seloc manual which covers so many models, I am confused so I want to ask... Is the pinion timed at all with the 2 driven gears? Is there a special way to install it? I don't think so but I wanted to ask. Also, do you really torque the castle nut to 200 ft lbs? That seems really tight. I indexed it with paint before removing and it didn't seem near that tight to remove. My special wrench for that large castle nut does not have the 1/2 drive square hole in it for a torque wrench either. Is a couple taps with the hammer and about a 1/16" past my index marks good? My S/N is

OW923460.. Thanks in advance!

OW923460.. Thanks in advance!