MyLord

Cadet

- Joined

- May 27, 2020

- Messages

- 29

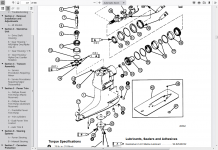

I have a 1995 bayliner 1952 model cuddy with a 4 cylinder 3 liter .Alpha 1 Gen 2

Gear In forward, outer shoe ball finger in shift mechanizmem on right. drive shaft locked to left and the shifter foot is aligned in the straight forward position.

I have rebuilt with new oem parts the bellows etc at the back end of the boat. I am now trying to install the outdrive .. as I do so it "stalls" at the 1 and 1/2 inch mark and does not seem to want to go in any further. ( Fat new O Ring?) I have searched and read you need more persuasion to get the outdrive in but before that, is there any other trick I can use to make it go inside? While looking down , the u joint closest to the outdrive as u look back to front is in the [_] position with the next u joint vertical ||.

failing all else What is a good persuasive tool that won't break the outdrive ? MMMany thanks

Gear In forward, outer shoe ball finger in shift mechanizmem on right. drive shaft locked to left and the shifter foot is aligned in the straight forward position.

I have rebuilt with new oem parts the bellows etc at the back end of the boat. I am now trying to install the outdrive .. as I do so it "stalls" at the 1 and 1/2 inch mark and does not seem to want to go in any further. ( Fat new O Ring?) I have searched and read you need more persuasion to get the outdrive in but before that, is there any other trick I can use to make it go inside? While looking down , the u joint closest to the outdrive as u look back to front is in the [_] position with the next u joint vertical ||.

failing all else What is a good persuasive tool that won't break the outdrive ? MMMany thanks

Last edited: