I found this in another thread- I still don't understand how to adjust timing with this distributor since it doesn't appear to move at all....

Good News!

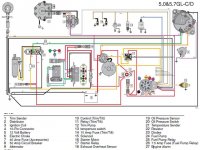

Ok, for anyone who is contemplating this swap, the VP Gi engine has the Delco EST distributor like the Voyager sold in kits around the web. I verified this by pulling up both distributors for the GL and Gi 5.0 VPs. The GL engines have a mechanical spark advance. The Gi engines have a reluctor, coil, and module. The module is VP p/n 3854003, which crosses to Delco D1965A and GM 10482830 or Sierra 18-5107-1. This is the marine module, and is different from the car module. The car module has a small advance curve as a limp mode, and will need to be hooked up to an ECM to calculate total spark advance. The marine modules have a total advance of 20degrees, in a straight linear progression that is all in by 3000 rpm. This means that if you have a TBI GM based engine, and you want to swap to a carburetor, all you need to do is pull the 4 wire plug from the ECM and cover the hole. You will need the shunt to set base timing.

I did a search for the GM 10482830 module, and found the advance curve etc. I also read about people who had been sold one of the $500 Voyager kits while converting a TBI engine to carburetor. They figured out later that they already had this ignition which the company who sold it to them also knew..........

So, the distributor that is on the engine will be getting some love and new parts so that there are spares on the boat in case of trouble.

Cheers,

Doug