No Title

Ok hopefully these load. The first four are the pictures that the seller gave me, based on these, I came up with the price I offered. The last two suggest what the hull looked like after demolition. In my defense, we found about a 4' long crack on the bottom of the boat that was non repairable. Otherwise I intended to strip it for donation or resale.

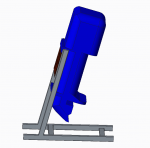

I picked up metal today to build an engine stand for the outboard and plan to have that mounted by the end of this upcoming weekend. Couldnt find any plans that I really liked, so I created my own. If it turns out, I'll share them here as well.

Ok hopefully these load. The first four are the pictures that the seller gave me, based on these, I came up with the price I offered. The last two suggest what the hull looked like after demolition. In my defense, we found about a 4' long crack on the bottom of the boat that was non repairable. Otherwise I intended to strip it for donation or resale.

I picked up metal today to build an engine stand for the outboard and plan to have that mounted by the end of this upcoming weekend. Couldnt find any plans that I really liked, so I created my own. If it turns out, I'll share them here as well.